#Industry News

FPI Shares Qatar World Cup Moments with You

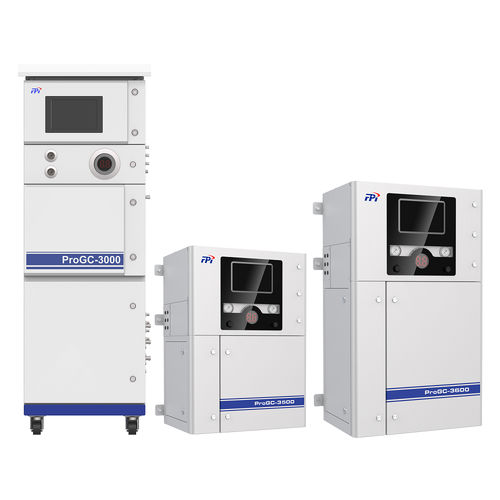

FPI ProGC Series

On November 20, teams competing in the 2022 World Cup's qualification phase spectacularly debuted in Qatar. Portugal vs Switzerland and Morocco vs Spain's quarterfinal results have recently been released. Coming up are the more competitive semifinals, so I'm wondering how your teams are doing, have they met your expectations?

The 2022 FIFA World Cup is the 22nd FIFA World Cup, the first in history to be held within Qatar and the Middle Eastern countries, and the second within Asia. In addition, the Qatar World Cup is the first World Cup soccer tournament to be held in the northern hemisphere during winter.

The World Cup & China

Even if the Chinese squad did not qualify for this year's World Cup in Qatar, there are still numerous "Chinese characteristics" in this tournament. As one of the eight iconic sports venues for the World Cup, China Railway Construction Corporation and Qatar collaborated to construct the Ras Abu Aboud Stadium. The outer structure of the stadium in Ras Abu Aboud, Doha, Qatar, comprises 974 shipping containers, the international area code for Qatar. These containers were all proudly provided by Chinese enterprises. In addition, there are Chinese elements everywhere, from football balls to national flags, souvenirs, public transit, and vacation complexes. Chinese referees Cao Yi, Ma Ning, and Shi Xiang are also officiating in this year's World Cup.

Qatar is rich in oil and gas resources, and its natural gas reserves are ranked third in the world behind Russia and Iran. According to the Gulf Times, Qatar's oil and gas revenues comprise more than 80% of the government's total revenue or roughly 24% of GDP. On November 21, Sinopec and Qatar Energy signed a long-term agreement to purchase and sell liquefied gas for 27 years. Qatar Energy provides 4 million tons of LNG annually to Sinopec.

In natural gas purification, transportation, liquefaction, and storage processes, Pro-GC industrial online chromatography analyzers independently created by FPI have demonstrated their speed, accuracy, and dependability in several domestic and international natural gas plants.

The People's Republic of China's Ministry of Science and Technology's High Technology Research and Development Center has announced the complete performance evaluation of the project "Engineering and Application Development of a Highly Reliable Industrial Online Chromatography Analyzer." FPI's independent development of the Pro-GC series industrial online chromatography analyzer under the National Key Research and Development Program resulted in an A-level evaluation of its research and development results.

The industrial online gas chromatographic analyzer adopts an automatic sampling, pre-processing, and sampling system with an explosion-proof and protective design and is widely applicable for the online analysis of the concentration of gas and vaporizable liquid components in various production stages of the petrochemical, coal chemical, natural gas, metallurgical, pharmaceutical, and power fields. The industrial online gas chromatograph differs from the laboratory benchtop chromatograph. It utilizes high-precision programmable column-cutting technology and column system sampling technology to rapidly examine the components being tested.

Features

1. Cabinet integration is unnecessary due to its low cost and straightforward installation.

Reduce the direct cost of evaluating the cabin's integration, the cost of hoisting during the installation process, and the total project cost from the customer's standpoint.

2. It can be easily deployed at any adjacent sampling station, decreasing sample loss and failure rate danger.

Since the analyzer cabin is not required, it can be placed close to the sampling site to reduce the transmission loss of the evaluated components and shorten the transmission delay time. It can also reduce the need for thermal insulation and heat tracing of the sample pipeline, which reduces the system failure rate.

3. Due to its modular design, the chromatographic column may now be replaced on-site in three hours instead of three days.

Adopting solid-state column box technology with special intellectual property rights, the column system is modified during the manufacturing process, thereby reducing the on-site column replacement time from 3 days or even a week to less than 3 hours.

4. Intelligent software-based analysis of the performance status of each fundamental component

Adopting the development concept of functional safety, redundant control of critical points and fault detection points are set in the chromatograph analyzer's control logic, which can judge the operation status of the chromatograph in real time, issue alarm signals, and isolate faults, thereby enhancing the analyzer's reliability.

For more details,please visit :https://www.fpi-inc.com/en/search_cp.html?key=ProGC