#Product Trends

Customer Stories:FPI CEMS-2000 Continuous Emission Monitoring System Supports Flue Gas Monitoring for Industrial Enterprises

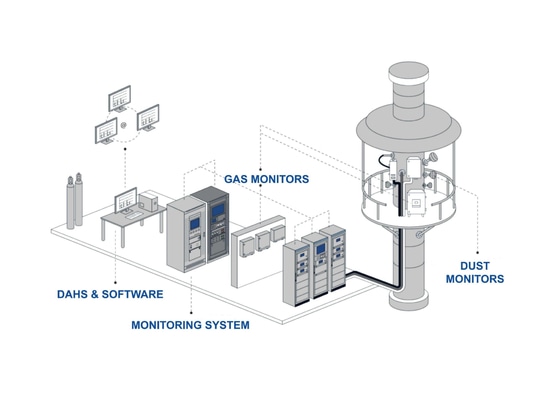

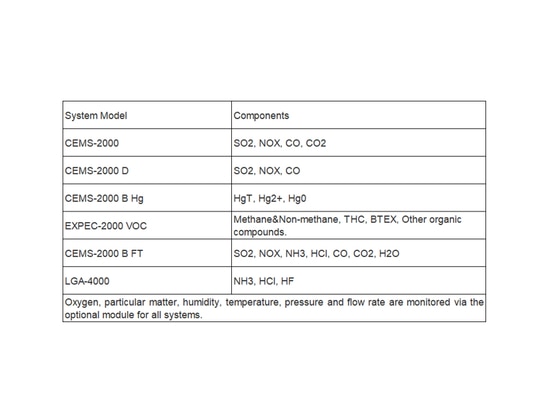

FPI CEMS provides an application gas analysis solution integrated with a particulate monitoring subsystem, TPF processing subsystem, gaseous (pollutant) monitoring subsystem, and data acquisition and processing subsystem, covering all the indicators and parameters to meet different customers' needs.

Such systems are extensively installed in industrial boilers, indicators and other mission sources, with real-time data uploaded to local authorities.

System Principle

The CEMS-2000 system uses in-situ extraction and a high-temperature sampling method (hot-wet sampling) to extract flue gas into the system for analysis. Among them, SO2 and NO are measured by UV-DOAS, oxygen (O2) by zirconium oxide, humidity (H2O) by limiting current, temperature (T) by platinum resistance, pressure (P) by the pressure sensor, and flow rate (F) by S-type Pitot tube.

Customer's Story

Y Company is a Korean company specializing in textile, fabric finishing, and fabric coating products. This project was for one of their plants in the north of Vietnam. To promote the continuous improvement of the ambient air quality and comply with the local environmental authorities' standards for plant emissions, Y Company started to cooperate with FPI.

FPI provided the CEMS-2000 multi-gas monitoring system for safety production and the efficient measurement of the flue gas concentration, such as SO2, NOx, CO, O2, dust, temperature, flow, and pressure. The solution package also includes FPI's on-site services, including project evaluation, system design, producing&delivery, installation&commissioning, and after-sales support.

Features:

1. UV-DOAS and NDIR technology allows simultaneous measurement of SO2, NOx, CO, and CO2 with a better signal-noise ratio than conventional technology.

2. The hot-wet extractive sampling system avoids condensation, corrosion and chalking.

3. Modular system design reduces the maintenance cost and gives a more stable system performance.

4. User-friendly interface and software provide a non-attended operation experience.

If any interests about CEMS products, please feel free to visit FPI's official online store: online.fpi-inc.com/