#Industry News

Customer stories: HURL and FPI's Innovative Partnership Lead the Way to Sustainable Fertilizer Production

FPI's Continuous Emissions Monitoring System

The fertilizer industry plays a crucial role in India's agricultural sector, which is the backbone of its economy.However, the production of fertilizers comes with its own set of environmental challenges. The fertilizer industry releases various pollutants into the environment, such as ammonia,sulfur dioxide, nitrous oxide, and particulate matter, which can have adverse effects on human health and the ecosystem.

In recent years, the Indian government has implemented several policies to regulate the fertilizer industry and reduce its environmental impact. One such policy is the National Ambient Air Quality Standards (NAAQS), which sets limits for pollutants in the ambient air. Under this policy, the government has established the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) to monitor air quality and enforce the standards.

In addition,the government has also implemented the Continuous Emissions Monitoring System (CEMS), which requires all major industries, including the fertilizer industry, to install online monitoring systems to track their emissions in real-time.

Against this backdrop, Hindustan Urvarak & Rasayan Limited (HURL) has been seeking ways to achieve sustainable fertilizer production, and FPI has been a valuable partner in this endeavor.Here are the story details:

Customer introduction:

HURL is a joint venture company aim to establish and operate state of the art environment friendly and energy efficient Natural Gas based new Fertilizer Complexes.

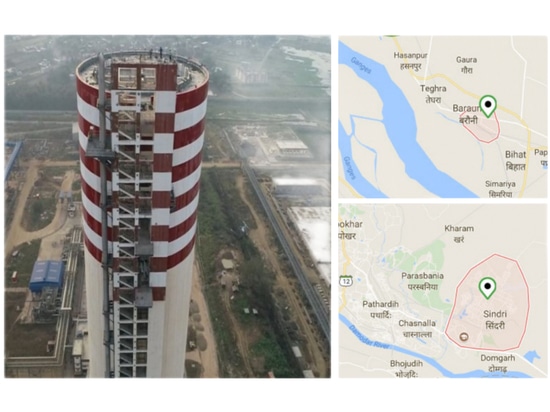

HURL at Barauni in Begusarai district of Bihar state can be seen as a corrective step towards reducing the growing supply gaps for fertilizer urea in eastern zone and to minimize import dependency. The existing Sindri Fertilizer unit of Fertilizer Corporation of India Ltd. is located in the district of Dhanbad in the state of Jharkhand. Sindri is well connected with major cities by rail/road.

In this project, We need to help the above two two fertilizer units to monitor the flue gas emission.

They need to monitor the levels of PM10(Urea), PM.2.5, SO2, NOX, Ammonia, Ozone and HC and displayed at a convenient location near the company gates or an important public place. The function of uploading the results of monitored data to the company’s website, and sending the data to CPCB and SPCB is also required.

In addition, customer also wants a dust analyzer to be used in the plant to control the urea dust in flue gas according to their prescribed standard technique.

Solutions FPI offered to the customer

According to the needs of customers, as a supplier with more than 20 years of industry experience, FPI believes that the following three points are the key factors for the success of the project:

1.Accurate and reliable analytical instruments

2.Fast and stable data upload system

3.Professional and responsible after-sales service team

So FPI’s solution package includes not only devices,but also on-site services,project evaluation, system design, producing & delivery, installation & commissioning, and after-sales support.

· Instruments FPI Provide:

CEMS-2000 Emission Monitoring System

Certified by TUV, CEMS-2000 is a multi-gas monitoring system aimed to continuously and reliably measure emissions such as SOX, NOX, CO from various industrial combustion.

LDM-100(D)

It is an in-situ dust analyzer based on the laser backscattering principle, which is mainly used to measure smoke and dust within the conventional ranges.

· Scope of Supply

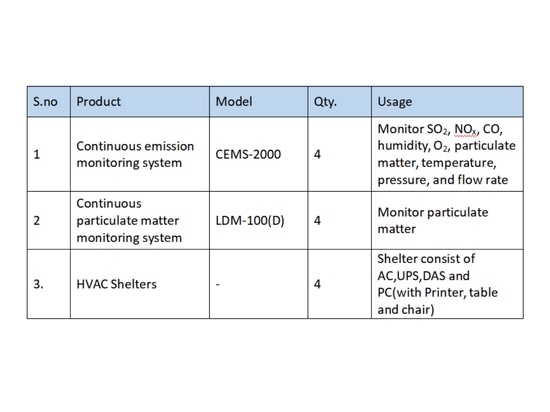

Please refer to illustration

After the basic plan is formed, what we need to do is to ensure on-time delivery and on-site installation and commissioning。

·Successful Field Implementation

FPI India service engineers selected an ideal location for the shelter to ensure accurate data, trained plant managers and staff on equipment installation and commissioning, and connected systems to the local environmental department's monitoring platform for data uploading. They also provided troubleshooting steps and supported fine production by helping enterprises optimize the balance between production and environmental protection through monitoring data.

However, in the implementation process, we also encountered many challenges.Firstly, the time of commissioning was the peak time of summers with the area temperature of 49 Celsius,which is extremely hot for working.Secondly,the location of the plant had highly inflammable substances, heat zones, temperature variations and toxic metals and chemicals. As a result, the risk of accidents, fatalities and health hazards is extreme.

In this harsh environment, FPI India service engineers devoted themselves to their duties, overcame difficulties through physical cooling, wearing masks, etc., and successfully completed the installation and commissioning work. In the end,The equipment of 8 measurement points was successfully put into operation, and completed the data upload according to the requirements.

Conclusion

The project was a resounding success, with installation and commissioning completed to the satisfaction of the client. The HURL Barauni and Sindhri Fertilizer Unit is now equipped with state-of-the-art FPI analyzers, allowing for real-time monitoring of SOX, NOX, CO, dust levels, and other gases originating from the fertilizer unit. Thanks to FPI India's smart, robust, and accurate monitoring system, HURL is now fully compliant with local environmental standards for plant emissions.

At FPI, we're proud to offer the best in monitoring technology and customer care. Here's why our customers love us:

√ Personalized on-site services and hands-on solutions by expert engineers

√ Budget-friendly FPI analyzers with accurate and reliable monitoring capabilities

√ Exceptional customer service that's prompt, friendly, and helpful

√ Stand-by support from our trained staff whenever you need it

√ Effortless maintenance thanks to our user-friendly monitoring systems

For more information,please visit: https://online.fpi-inc.com/.