#Product Trends

How FPI's ICP-MS Provides Rapid Detection of Agricultural Products at the Chinese Academy of Agricultural Sciences

The World Health Organization estimates that over 600 million people become ill, and 420,000 die each year from eating food contaminated with bacteria, viruses, parasites, toxic or chemical substances.

However, these numbers represent only the "tip of the iceberg," as comprehensive surveillance data on foodborne illnesses are unavailable worldwide. If food is unsafe, humans will not benefit from its nutritional value, nor will they be able to grow and develop.

To explore the role of FPI's SUPEC-7000 series full-featured ICP-MS in rapidly detecting agricultural products, food security and developing new methods for rapid, high-throughput analysis and testing of complex matrices. Let's learn more about the role of FPI's SUPEC-7000 series ICP-MS in developing new methods for rapid and high-throughput analysis of complex matrices!

ICP-MS Technology with Rapid Injection Module

FPI SUPEC-7000 series ICP-MS is equipped with the EXPEC-726 fast injection module, which adopts a six-way valve design to push the sample directly to the atomizer through the dosing ring, reducing the injection time, accelerating the rinse rate, automatically switching between injections and rinses modes, reducing the effect of memory effect to a low point, significantly improving the analysis efficiency, and meeting the high throughput sample requirements of laboratories. The sample is automatically switched between feed and rinse mode, which greatly improves the analysis efficiency and meets the needs of high throughput samples.

Fast sampling, fast peak

The sample is extracted by a complete PTFE diaphragm pump and filled with the reservoir ring within 2s. The peak is produced in 8s and can be analyzed after 15s.

Improved efficiency

Due to the fast injection speed and signal stabilization, analysis is performed simultaneously with rinsing, dramatically increasing analysis efficiency and allowing one instrument to be used as two or even three.

On-line cleaning

Adopting interval carrier flow flushing technology, the carrier flow continuously cleans the inlet pipeline, effectively improves the flushing effect of the sample pipeline, ensuring that the pipeline is free of contamination and significantly reduces the memory effect.

Chemical and strong acid corrosion resistance

The valve parts are all perfluorinated material, matched with high-purity PFA piping, which can resist strong acids and other reagents with high reliability and universality.

Low cost

The short total sample analysis time reduces argon consumption. The short injection time, most of which is carrier flushing, reduces the cone mouth effect, thus substantially reducing cone cleaning and maintenance requirements. Compared with conventional analysis, carrying the rapid injection module can significantly increase the analysis rate by 2-3 times, solving the problem of high throughput analysis.

ICP-MS technology and electrothermal evaporation coupling

At the present stage, the confirmatory assay, which plays a major role in detecting heavy metals, is mainly based on liquid injection. The pre-processing of the sample digestion is time-consuming and laborious. Electrothermal evaporation (ETV) is a solid injection technique that uses an electric current to heat the sample so that the element to be measured enters the instrument as an aerosol, which is highly applicable.

ETV-ICP-MS realizes the combination of graphite furnace and ICP-MS, which can realize the direct injection of solids such as soil and minerals and the direct injection of complex matrices such as soy sauce, seawater, and high-purity sulfuric acid, etc. It is widely used to determine metal elements in various substances such as the environment, food, biological samples, and industrial products.

EXPEC-723 solid direct injection system (ETV) coupled with ICP-MS combines the advantages of ETV and ICP-MS, which can determine multiple elements simultaneously with high measurement efficiency, good accuracy, and strong anti-interference ability. It is a highly efficient, rapid, green, and practical value analysis technique, which can provide an adequate technical means for on-site and rapid detection of heavy metals in large-volume samples.

· Based on the combination of graphite furnace electro-thermal evaporation technology and ICP-MS technology, solid samples are directly injected into the sample for analysis without the need for ablation, which greatly improves the analysis efficiency and is a typical green analysis technology.

· Based on the direct dissociation technology of high temperature solid samples in graphite furnace, it is especially suitable for difficult to dissolve, difficult to disintegrate, and various conventional difficult to analyze samples such as organic and soil samples.

· Up to 3000 ℃ high temperature can dissociate all samples, through PID infrared temperature control technology to achieve perfect temperature control, programmable temperature rise function for different samples of different elements analysis.

· Combined with AGOD argon online dilution system to effectively eliminate matrix interference and improve analytical accuracy.

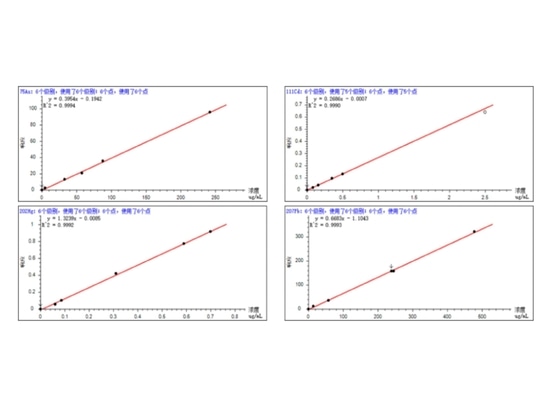

The ETV-ICP-MS showed good accuracy, precision and stability in the analysis of soil samples. The linearity coefficients of the established standard curves were all greater than 0.999, and the test method was simple, easy to perform and realistic.

Scientific instruments are the "multipliers" of industrial production and the "pioneers" of scientific research. With the continuous development of science and technology, FPI will persistently and deeply plow to become the world's leading scientific instrument manufacturer.

If any interests in this product, please feel free to visit FPI's official online store: https://online.fpi-inc.com/