#White Papers

The Role of Sample Gas Coolers in Ensuring Accurate Gas Analysis

Maintaining Optimal Measurement Conditions Through Advanced Cooling Solutions

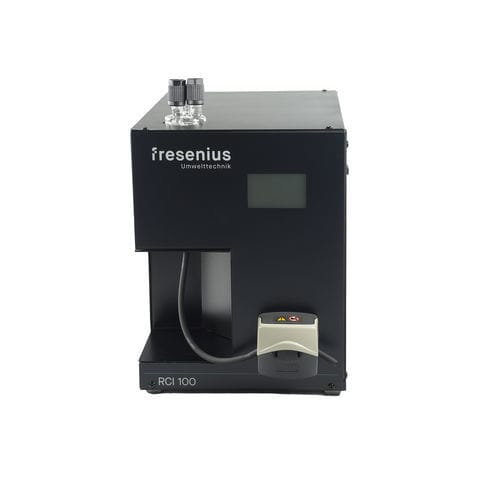

In gas analysis, the accurate measurement of gas composition is vital for process control and equipment protection. One of the key factors affecting measurement precision is the dew point—the temperature at which water vapor condenses in the gas stream. Sample gas coolers, like the Fresenius RCI series, are designed to manage these conditions, ensuring that gas samples are delivered with minimal residual moisture.

Key Technical Features of our RCI Sample Gas Coolers:

Precise Dew Point Stabilization

The RCI series maintains a stable dew point of 5°C, with residual humidity reduced to 0.86 vol-%. This stabilization is achieved through efficient cooling mechanisms, which ensure consistent conditions for gas analysis even in fluctuating environmental settings.

Protection for Analytical Equipment

Excessive moisture in gas samples can damage sensitive components such as sensors and detectors. By reducing humidity levels, sample gas coolers extend the operational life of measurement systems and lower the frequency of maintenance interventions.

High Cooling Capacity and Flow Rates

The RCI series supports flow rates of up to 260 L/h with a cooling capacity of 90 kJ/h. This makes it suitable for high-throughput applications while maintaining precise control over gas conditions.

Material Durability and Easy Maintenance

The heat exchangers, constructed from Duran glass with optional stainless steel or PVDF materials, offer high resistance to corrosion and wear. These components are modular and easily removable, simplifying cleaning and maintenance tasks.

Condensate Management System

Integrated condensate removal systems, such as peristaltic pumps and removable condensate hoses, enhance operational efficiency. These features minimize sample contamination and ensure a continuous flow of conditioned gas.

Data Integration

Advanced connectivity options, including Profibus, Modbus TCP, and Ethernet IP, enable seamless integration into existing process control systems. A resistive touch display offers straightforward navigation and configuration.

Application Scope

Sample gas coolers are utilized in a wide range of industries, including:

- Refineries: Managing gas samples for hydrocarbon processing.

- Pharmaceutical Manufacturing: Ensuring accurate analysis in controlled environments.

- Recycling Plants: Optimizing emissions monitoring systems.

Technical Specifications

- Residual Humidity: 0.86 vol-%

- Dew Point: 5°C

- Maximum Flow Rate: 260 L/h

- Cooling Capacity: 90 kJ/h

- Materials: Duran glass, with options for steel and PVDF

- Connectivity: Profibus, Ethernet IP, Modbus TCP

Conclusion

By effectively managing dew points and reducing humidity levels, sample gas coolers ensure the reliability and precision of gas analysis systems. With robust construction, easy maintenance, and advanced data interface capabilities, the Fresenius RCI series provides a reliable solution for industries where gas analysis accuracy is critical.