#Industry News

The Importance of CNC Robotics in Manufacturing

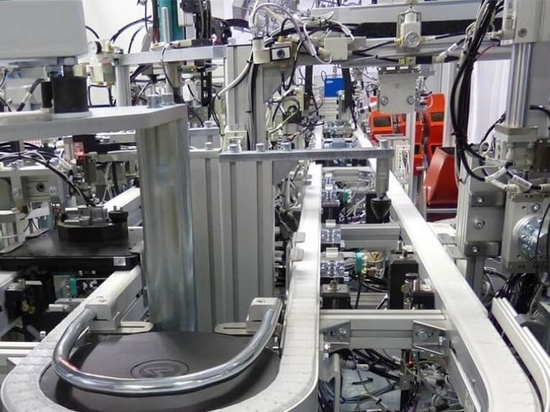

Linear Motion System for Positioning Applications

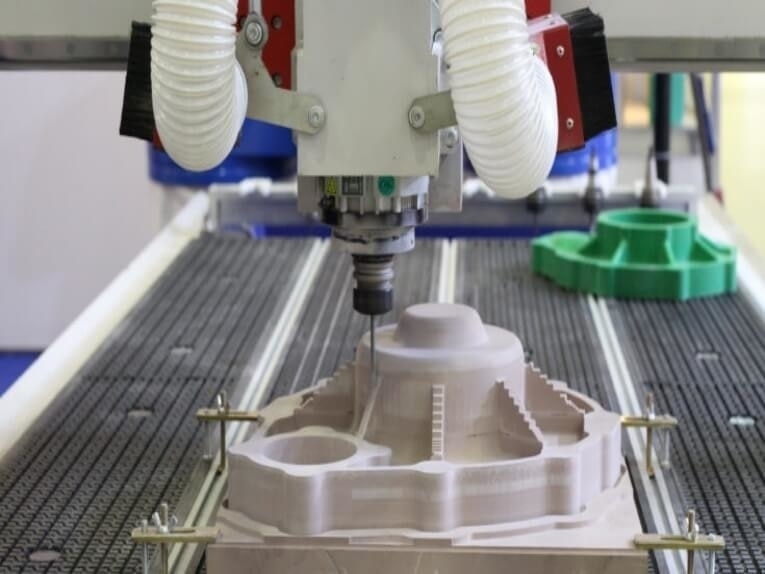

CNC machining has transformed the manufacturing world without a doubt, and the effects of that can be seen on a daily basis. Manufacturing has become faster, goods have attained better quality, and they are a number of other improvements that have come into effect in the manufacturing space. The following are some of the reasons why CNC Machines are vital in manufacturing.

Fast Production

In the past, a simple broken piece of a machine or the absence of an individual with the skills needed to run a particular machine was enough to slow or even halt the production process. But with CNC robots, that’s no longer an issue. Rather than wait for months for repairs to be made, a missing or broken part can be repaired within hours and days at most, with operations resumed immediately. This ensures that nothing much is lost and orders are met at all times. Once you have set up CNC machining in your factory, make sure you have enough warehousing storage for the goods that will be produced, as you may find yourself in trouble if you can’t keep up with the production speeds.

Reliability

You can always depend on CNC robots to come through with the work as they are designed to handle their work without any supervision. All you need is to set the program how you want it to run and hit the on button. This gives people the chance to concentrate their efforts on other processes, and this further improves the quality of the products at the end of the day. CNC machines rarely break down even when pushed to their limit. This is something that cannot be achieved if human workers are in the equation as they tend to get tired, and once fatigue sets in, precision wavers and the quality of the end products drop down.

No Need for Expertise

Work that used to require years of experience for an individual to be able to handle with minimum flaws can now be handled quickly from the moment the CNC machine is installed with better accuracy. Having to train people to handle one part of the production process can be very expensive, and there’s never any guarantee that they’d stick around for long for the company to recoup their investments. This used to put manufacturing enterprises in a very tight spot. However, with CNC machining, all that’s needed is a functioning program, and the rest is left to the CNC robots.

Cost-Effective

With less human workforce that used to gobble up the profits in the form of salaries, manufacturing plants are now able to save a lot of money by investing in CNC machines that can work for long without breaking down or getting tired. Although their initial costs are very high, once they are set up and running, the work they put in can recoup the initial investment within months, making them a better investment in the long run. The money that companies save in the process can then be reinvested into the company making more improvements that increase production and the quality of the end products.

Safer

Factory accidents are no longer as common as they used to be in the past, thanks to a reduced human workforce. CNC robots are given more space to operate, and they are usually in strategic places that are far from people. With limited interactions between man and machine, the chances of accidents happening are almost reduced to nil, and this has made working safer while reducing the costs that go into compensating injured workers. When dealing with processes like making construction materials, welding, metal cutting, and other high intensive, you can be exposed to heat and loud noises, which can lead to health complications, CNC robots, on the other hand, are immune to such things and can be used without any reservations.

Increased Quality and Affordability

One of the direct advantages of CNC machines, as already mentioned, is fast production that increases supply. Once the supply outstrips the demand, things become cheaper, and this is to the benefit of the consumers. On top of all that, the increased production doesn’t compromise the quality of the products in any way; therefore, people still get the same level of products as before but at reduced prices, and this further boosts purchasing habits, which in turn increases profits to the manufacturer.