#Product Trends

What is a Gantry System in a 3D Printer?

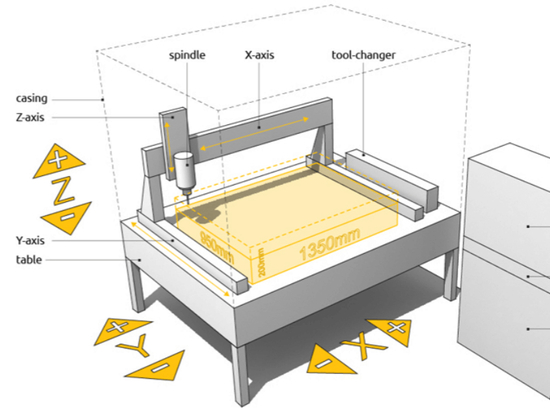

Turn a CNC router into a concrete 3d printer.

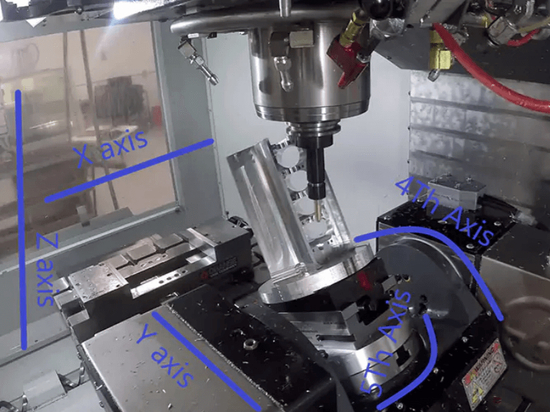

A Gantry is what supports and moves a printer’s extruder or print head in a 3d printer. It usually comprises a set of rails, belts, stepper motors etc., which control very precise positioning involved in layer deposition precisely as required. The resolution, speed and general quality of printed objects are hinged on the gantry system’s ability for movement along X, Y (and sometimes Z) axes.

1. Defining Gantry Systems in 3D Printing

Different types of 3D printing gantry systems are grouped into several categories each with its own characteristics and uses. The commonest ones include Cartesian, CoreXY, and Delta gantry systems. Simple and reliable cartesian gantry systems use linear motion along the X, Y, Z directions. The corexy system has a more advanced belt driven mechanism enabling faster movements and higher precision ideal for manufacturing more complex prints at a quicker pace. The three armed delta gantries offer fast accurate vertical movement that is helpful in large sized 3D printed objects. Knowing the mechanical distinctions of these systems will enable you select the right one for your specific printing needs therefore improving your 3D printing experience altogether.

2. Components of a 3D Printer Gantry

The function and performance of a 3D printer gantry depend on its components. These are some of the most common:

Rails and Rods: They act as the framework for the movement of print head or extruder, thereby ensuring stability and smoothness in motion in the X, Y and sometimes Z axes.

Stepper Motors: These precise motors determine how the gantry moves along all three axes. They are important for accurate placing and layering during printing.

Belts and Pulleys: Belts and pulleys, mostly as part of CoreXY systems, facilitate the transferal of movement from stepper motor to gantry hence enabling fast and exact movements.

Linear Bearings and Carriages: Components like these enable rails to be slid smoothly with no friction by providing a way for facilitating this kind of travel to the print head.

End Stops and Sensors: This is what sets up starting point calibration for gantry while also making sure that a print head will not move away from defined print area.

Frame: It’s a solid construction which keeps all main parts of gantry together thus ensuring steadiness during printing process with minimum vibrations.

Understanding these components helps you maintain your 3D printer’s gantry system effectively for high-quality prints that are reliable too.

3. How Does the Gantry Move?

The process of a 3D printer gantry’s movement is highly coordinated, and it involves several components. This movement is centered on stepper motors that convert electrical pulses into precise mechanical actions. These motors are coupled to the gantry through belts or lead screws, which provide motion along the defined axes. Rails and rods give direction for the gantry to move as linear bearings and carriages maintain it within a smooth and accurate path as they cause frictionlessness. Besides, end stops and sensors are vital in setting up the starting point of the gantry so that it never goes beyond its printing area. In this regard, comprehension about these mechanisms helps in optimizing performance of a gantry for producing high quality 3D prints.

4. How Does a Gantry System Work in 3D Printing?

In 3D printing, a gantry system is an arrangement of several mechanical and electronic components that enable precision movements of the print head throughout the designated build volume (print area). Stepper motors normally receive digital signals from a controller in form of electrical current pulses which sequentially translates them into individual step rotation to drive belts or lead screws that relay this motion to the gantries. Stable pathways are provided by rails and rods along which these canopies traverse while linear bearings together with carriages ensure there are no hitches as well as accurate movements. For instance, end stoppers and sensors define where beginning occurs as well as mark boundaries; thus they keep off demarcated spaces during such events like moving outside set priniting areas.This collection aside facilitates exact deposition of material resulting in fine quality three-dimensional prints produced.

5. Stepper Motors

Stepper motors are indispensable in 3D printing because they can accurately control the movement of the print head and build platform. This is achieved by converting electrical pulses into discrete mechanical steps. In contrast with traditional motors, stepper motors move through fixed increments that permit accurate positioning without requiring feedback systems. For example, when it comes to 3D printing, each layer must be placed down with precise accuracy to guarantee high-quality outputs. This is why stepper motors are also so reliable as to remain in position even when not powered up, hence providing another level of stability and consistency during the printing process.

6. Understanding Rail and Carriage Mechanisms

Rail and carriage mechanisms have fundamental roles in a 3D printer since they help smooth and precisely guide its movements. Usually these mechanisms encompass linear rails which are stiff tracks along which carriages run. Linear bearings inside the carriages ensure that there is minimal friction while allowing for precise motion of either the print head or build plate. Overall precision and accuracy of a printer depend on design and quality of its rails and carriages. By holding tight tolerances and enabling smooth travel, these mechanisms make possible detailed, high quality 3D prints creation.

7. Importance of Axes: X, Y, and Z

3D printing is highly dependent on three axes that are X, Y and Z as they delimit the three dimensional region over which the print head or build plate moves. The X-axis and Y-axis are in charge of horizontal movements with the X-axis normally handling left and right motion while Y-axis takes care of forward and backward motion. However, Z-axis manages vertical movement thereby allowing the print head or build platform to move up or down. Accurate arrangement of each layer during 3D printing is governed by preciseness on these axes; it is this precision that is required to produce detailed and high quality models. When working together along these three tridimensional axes, a 3D printer can achieve astonishingly accurate representations of complex geometries.