#Product Trends

Why are Gantry Systems Essential for Large Scale 3D Printing?

precision, stability, and expansion

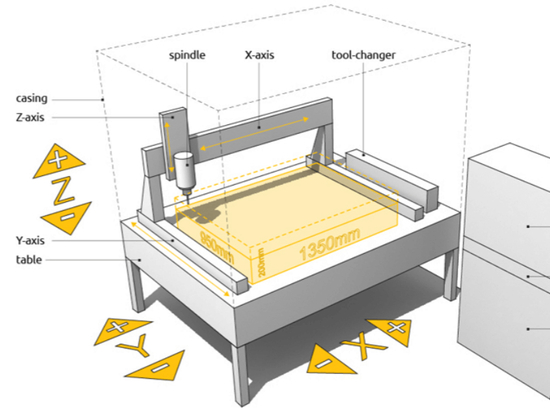

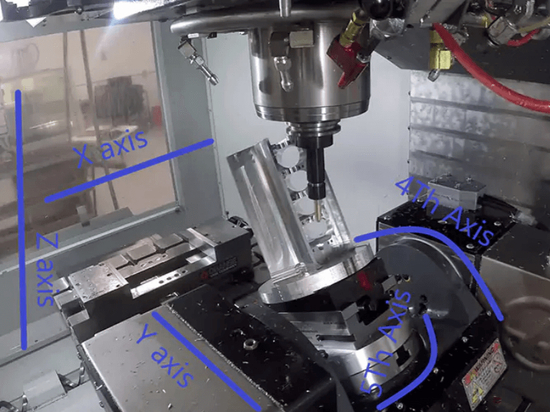

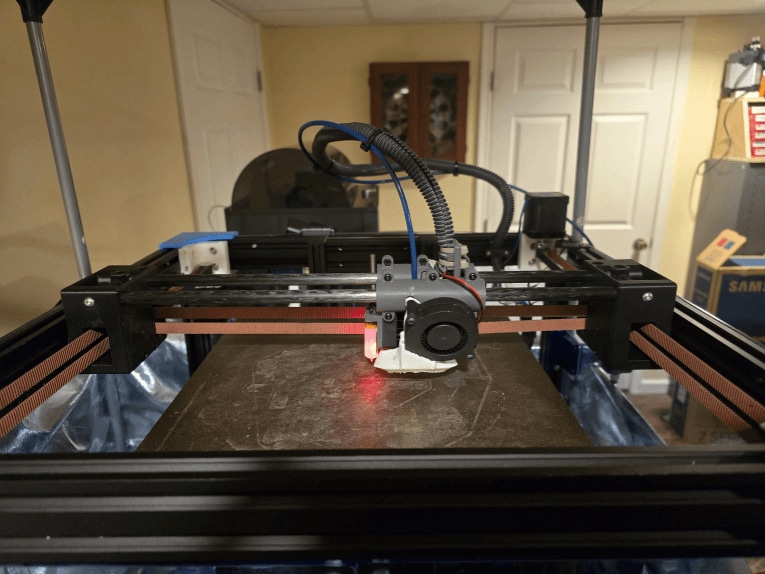

The main reasons why gantry systems are important for larger-scale 3D printing are that they are more rigid and capable of controlling a larger volume. By the way, gantry systems have stronger structures that can resist bending and vibrations during large prints. They have greater weight-bearing capabilities, which allow them to yield large components with more intricate features hence making them indispensable within the industrial sphere where precision, stability, and expansion must come together.

Advantages in Build Volume

Gantry systems possess considerable advantages in build volume due to their inflexible and fixed design that allows for bigger prints with high accuracy. As shown by some of the top sources, gantry systems reduce deflection and vibration in order to accommodate larger print sizes. Therefore, large-scale projects tend to rely on stability of this kind because it brings about higher print quality as well as dimensional accuracy. Furthermore, wider underpinning frameworks in printers using gantries support heavier loads and provide access to complex geometries rendering them more suitable for industrial scale operations.

Precision and Stability

Gantry systems, which are known for their strong architectural design, are the best at ensuring accuracy and stability in 3D printing. Gantry systems have a rigid structure that eliminates any deflections and vibrations thereby undermining print accuracy as stated by leading sources. As such, even complicated geometries can keep the required dimensions and details. In addition, gantry positioning system guarantees that each layer is stacked uniformly throughout the build process to ensure structural integrity of a printed object. The use of gantries in motion control means that they have excellent stability compared to other types of printers, making them very reliable for industrial applications requiring high precision and large-scale products printing.

Applications in Large Scale Manufacturing

The incorporation of precise yet intricate designs in huge build volumes has made gantry systems gain popularity as the heart of many large scale manufacturing activities. According to major industry sources, these machines have found prominence in aerospace because they create light structural parts through complex structures with minimal wastage of materials. The automotive sector benefits from gantries’ use in 3D printers for rapid prototyping and production of vehicle parts hence reducing time taken to develop new products as well as costs involved. Furthermore, the construction industry is using on-site building component 3D printing provided by gantrysystems which boosts productivity while minimizing labor expenses. Therefore, this flexibility and accuracy are what make it necessary for developing large scale manufacturing using gantry systems.