#Industry News

What Are the Challenges and Limitations of Gantry 3D Printing?

Challenges and limitations about gantry 3D printing

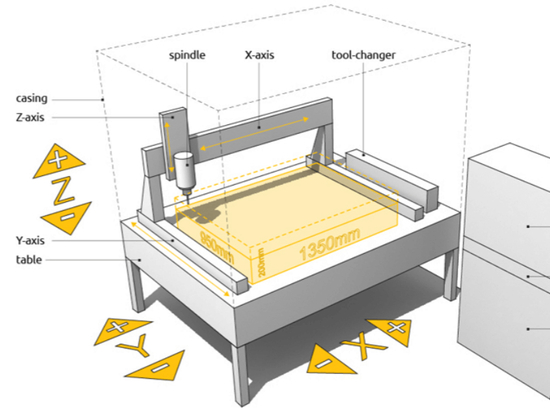

Gantry 3D printing is useful because it is precise and available to many people, but it has some challenges and limitations. One of the major difficulties is the size of build volume which depends on gantry system’s dimensions. Besides, keeping axes precisely calibrated is important because slight deviations may result into printing defects or failures. Also speed of printing is a limitation since it takes long times producing large or complex objects due to layer-by-layer approach. Moreover, material constraints restrict certain materials from being used in gantry 3D printers. Lastly, the printer’s reliability can be affected by mechanical wear and hardware malfunctions over time resulting in increased maintenance costs.

Structural Limitations and Rigidity

In gantry 3D printing, there are structural limitations and rigidity concerns. Accuracy and precision in printed objects require a stable and rigid frame. Frame stiffness variations make vibrations and oscillations during print process that can negatively affect print quality. In addition, sagging or misalignment due to weight of print head as well as moving components over time results to cumulative errors for layer deposition. Thus, such issues are minimized by having a rigidly designed gantry system which helps enhance the overall reliability plus performance of the printer as a whole. However, achieving such rigidity often involves high manufacturing costs and complex assembly processes limiting both makers and manufacturers by this factor too.

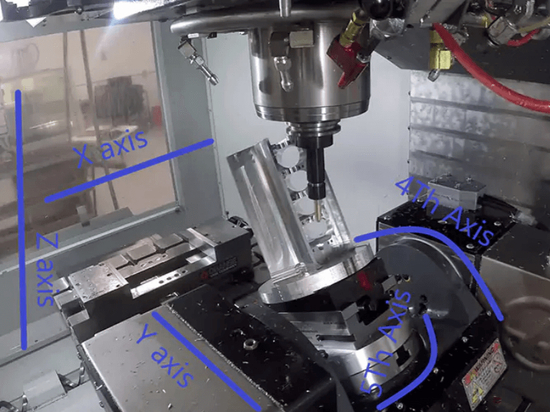

Precision and Tolerance Issues

Gantry 3D printing relies heavily on precision and tolerance, which determine the quality and accuracy of the final product. One common source of inaccurate prints is poor resolutions that are related with stepper motors as well as control systems in this type of printers. Errors as small as slight deviations from a straight line can accumulate over large heights resulting in significant errors from the intended dimension. Besides, gantry 3D printer’s tolerance also depends on its components such as rails, belts and bearings. High accuracy parts can reduce these deviations but they increase the cost of the machine overall. Additionally, thermal expansion during printing due to material properties or uneven calibration worsens print tolerances resulting into warping or layer misalignment. For that reason maintenance must be routine so that such problems cannot happen leading to consistent quality prints.

Common Mechanical Failures and Solutions

Typical mechanical issues seen in gantry 3D printers are belt slippages, layer shifting and nozzle clogs . Quite often belt slippage occurs due to worn-out or under tensioned belts which may be fixed by inspecting them regularly tightening them when necessary or replacing totally . Layer shifting usually emanates from loose components like pulleys or motor mounts being not aligned properly . This problem can be avoided simply by securing all parts firmly and periodic verification of proper alignment . In most instances nozzle clogs arise because of debris accumulating inside the hotend or filament blockage caused by excessive heat applied on it. Such incidences can be greatly curtailed through cleaning nozzles frequently and using high-quality filaments only The useof a filament filter will go a long way in keeping impurities out ofthe nozzle itself . Regular service routines coupled with proper care for components like these however will improve significantly the overall efficiency and dependability of gantry 3D printers.