#Product Trends

Cartesian Handling System: 2D Motion & 3D Motion

Customization and Versatility

Cartesian handling systems as serial kinematics have main axes for straight-line motion and auxiliary axes for rotation. The system acts simultaneously as guide, support and drive and must be integrated into the application’s complete system regardless of the handling system structure.

Standard mounting positions

All Cartesian handling systems can be installed in any position in the space. This allows the mechanical system to be adapted ideally to the conditions of the application. Here is a look at some of the more common designs.

Two-dimensional – These Cartesian handling systems are divided into the categories of cantilevers and linear gantries with their movement in the vertical plane, and planar surface gantries with their movement in the horizontal plane.

A 2D cantilever consists of a horizontal axis (Y) with a vertical drive (Z) mounted on the front of it.

A linear gantry is a horizontal axis (Y) secured at both ends, left and right. A vertical axis (Z) is mounted on a slide between the two end points of the axis. Linear gantries are usually slim, with a rectangular vertical working space.

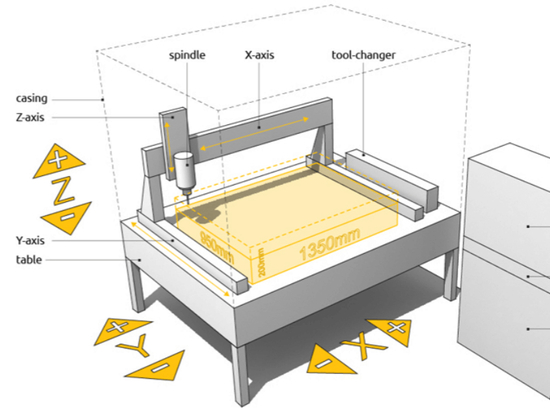

A planar surface gantry consists of two parallel axes (X) linked by an axis (Y) perpendicular to the direction of movement. Planar surface gantries can cover a significantly larger working space than robot systems with delta kinematics or SCARA with their circular/kidney-shaped working spaces.

In addition to the conventional configuration with individual axes, linear gantries and planar surface gantries also take the form of complete systems with a fixed mechanical combination with a rotating toothed-belt as the driving component. The low effective load makes them suitable for high capacities (picks/min) with corresponding dynamic response.

Three-dimensional – These Cartesian handling systems are divided into the categories of cantilevers and 3D gantries with movements on both planes.

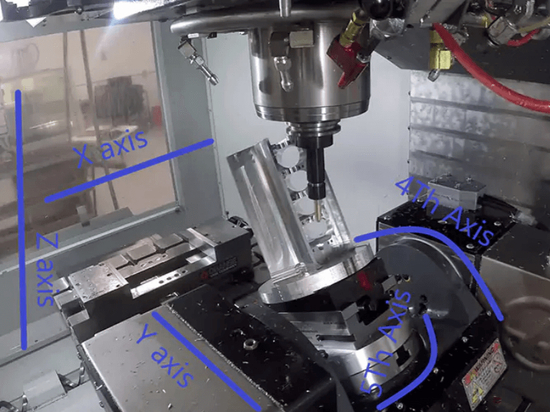

3D cantilevers are two axes (X) mounted in parallel plus a cantilever axis (Y) perpendicular to the direction of movement, with a vertical axis (Z) mounted on the front of it.

3D gantries consist of two parallel axes (X) linked by an axis (Y) perpendicular to the direction of movement. A vertical axis (Z) is mounted on this perpendicular axis.

Note: With planar surface, linear and 3D gantries, the force is applied between the two points of support of the horizontal axes. The horizontal axis on the cantilever acts as a lever due to the load suspended on its end.

Simpler programming required

The degree of programming required depends on the function: If the system only needs to move to individual points, quick and simple PLC programming is sufficient.

If path movement is necessary, such as when applying adhesive, PLC control is no longer sufficient. In such cases, conventional robot programming is required for Cartesian handling systems too. However, the control environment for Cartesian handling systems offers a large range of possible alternatives when compared with conventional robots. Whereas conventional robots always require use of the manufacturer’s specific control system, any PLC can be used for Cartesian handling systems, in the version with the best range of functions for the application’s requirements and complexity. This means customer specifications can be adhered to and a uniform control platform can be implemented, including a uniform programming language and program structure.

With conventional robots, complex programming is often required. Consequently, a great deal of work is needed to use 4- to 6-axes systems for mechanical tasks. For example, all 6 axes always need to be moved at the same time for straight-line travel. It is also difficult and time-consuming to program “right arm to left arm” in conventional robotic applications. Cartesian handling systems offer excellent alternatives here.

Energy efficiency is high

The foundations for energy efficient handling are laid even when selecting the system. If the application requires long dwell times in certain positions, all axes on conventional robots are subject to closed-loop control and must continuously compensate for weight force.

With Cartesian handling systems, it is usually only the vertical Z axis which needs to apply force continuously. This force is required to hold the effective load in the desired position against gravitational force. This can be achieved very efficiently using pneumatic drives, as these do not consume energy in their holding phases. A further advantage of pneumatic Z axes is their low dead weight, which means that smaller sizes can be used for the mechanical components of X and Y axes and their electric motor. The reduced effective load leads to a reduction in energy consumption.

The typical strengths of electric axes come to the fore especially in the case of long paths and high cycle rates. Therefore, they are often a very efficient alternative for X and Y axes.

Conclusion

In many cases it is more efficient and economical to use Cartesian handling systems instead of conventional robot systems. For a large range of applications, it is possible to design an ideal Cartesian handling system because:

• The systems are configured for the requirements of the application in terms of optimum paths and dynamic response, and are adapted to the load.

• Their mechanical structure makes them easy to program: for example, only one axis needs to be activated for vertical movements.

• Their optimal mechanical adaptation makes them energy efficient, for example, by switching off the energy supply when at rest.

• Cartesian handling systems are space-optimized for the application.

• Standard, mass-produced components allow Cartesian handling systems to be an attractively priced alternative to conventional industrial robots.

And last, but not least: With Cartesian handling systems, the kinematics are defined by the application and its peripherals, not the other way around.