#Industry News

One Stop Solutions of Mixed Municipal Household Waste (MSW) Sorting Center

GEP ECOTECH intelligent crusher shredder machine for municipal solid waste

The waste sorting has stepped from the 1.0 era to the 2.0 era. The domestic waste sorting center has formed a complete closed-loop mode of front-end classified delivery, middle-end classified collection and transportation, end classified treatment.

In response to the call, to achieve the goal of harmless, reduction, resource utilization and industrialization disposal of waste proposed by the country. With rich waste disposal experience, GEP focuses on providing customers withe a complete one-stop waste sorting center with high efficiency, energy saving, cost optimization, duration guarantee and after-sales care from scheme design, equipment manufacturing, installation and construction to specialized intelligent operation and maintenance services solutions. According to the actual situation of the project and the composition of domestic waste, different.

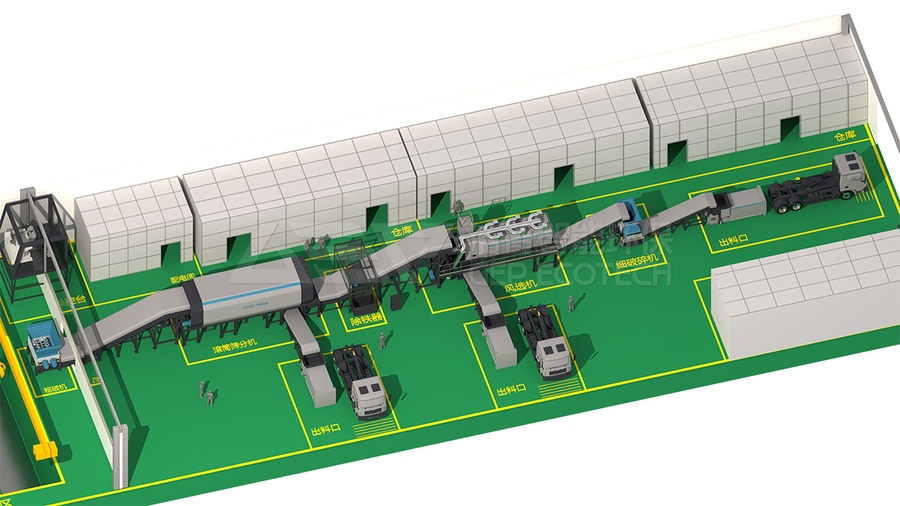

EPC project of domestic waste disposal center

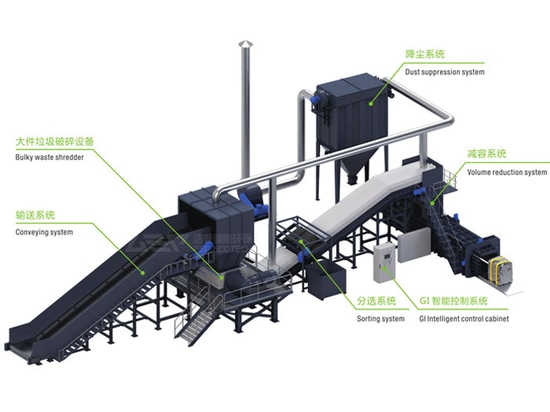

Bulky waste disposal line

The production line of GEP bulky waste and garden waste consist of conveying system, shredding system, magnetic separation system, intelligent monitoring system and intelligent dust suppression system. It takes less than one minute for a waste mattress to be loaded, shredded, sorted and discharged. Mechanical shredding replaces manual disassemble improves work efficiency and working environment greatly, at the same time it also reduces the safety risks of shredding and disassemble.

Waste textile disposal line

GEP waste textile disposal line is mainly composed of conveying equipment, intelligent double-shaft shearing shredder and professional dust suppression device. According to the characteristics of cloth waste, the fixed cutter adopts a unique cutter shaft structure and anti-winding design, which effectively prevents cloth fabric from winding and greatly improves the shredding efficiency of the double-shaft shredder.

Kitchen waste disposal production line

GEP kitchen waste disposal system adopts the process of "pretreatment, rough separation, fine crushing, separation, pressing and resource disposal". The process flow is short, the function is complete and the degree of automation is high, which can ensure the kitchen waste can be treated more effectively and innocuously, reduce the amount of treatment, realize the fine separation of kitchen waste, ensure the smooth operation of the process production line and meet the needs of process production. Realize the maximum resources utilization of kitchen waste.

Buried type sewage disposal system

Buried sewage treatment system is a kind of sewage biological treatment system with biofilm as the main body of purification. It has the advantages of stable and reliable technical performance, good treatment effect, low investment, less occupation of land, convenient maintenance and so on. After filtration, stirring, precipitation and disinfection of sewage, the effluent standard can meet the national discharge standard.

Six functions of GI intelligent monitoring system

GEP GI intelligent monitoring system makes use of Internet of things and big data technology to build a comprehensive information processing platform, which can effectively realize real-time supervision and statistics of the production situation of the whole production line. Through real-time visual monitoring video to see the the workshop site, timely grasp of the operation of the equipment, know the progress of waste disposal in real time in room. Once the equipment fault is detected automatically by the control system, the system will initiate abnormal early warning, realize fast fault location and reduce the incidence of fault.