#Industry News

NORD’s expertise in end-of-line packaging

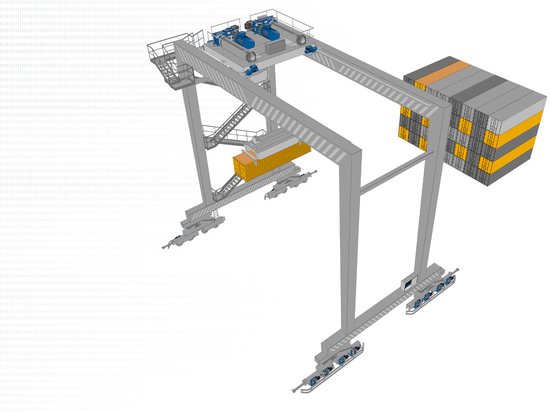

In end-of-line packaging, the last stage of the packaging process, high loads are moved via long travel distances. For this purpose, NORD offers individual, powerful, economic and reliable drive systems.

In end-of-line packaging, the last stage of the packaging process, high loads are moved via long travel distances. For this purpose, NORD offers individual, powerful, economic and reliable drive systems.

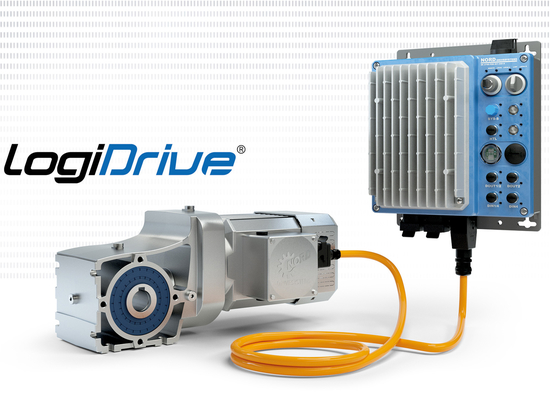

Whether packaging, strapping or palletising machines or conveyor systems – NORD offers modular drive concepts from a single source: “Our geared motors, motors and decentralised frequency inverters are fully matched and optimally adjusted to the end-of-line packaging’s requirements”, says Stefan Blust, Industry Sector Manager. “We implement tailor-made solutions for the respective application.”

Advantages of NORD drive technology at a glance:

- Flexible integration through various mechanical (flanges, shaft sizes) and electronic bus interfaces.

- Economic decentralised asynchronous and servo drives with controllable frequency inverters instead of conventional servo technology

- Less installation efforts and installation space; control cabinets and wiring are omitted

- Savings of up to 50%, depending on the application

Reliable decentralised drive systems in packaging machinery

Due to their high inertia, NORD asynchronous motors offer decisive advantages for end-of-line packaging. They ensure easy (movement) control and when moving heavy loads – large gear ratios solved with extensive and expensive gear units are omitted. Furthermore, they ensure ultimate process stability and a low risk of damage due to reduced vibrations. NORD asynchronous and synchronous motors are also characterised by their long service life and low downtimes. They are easy to maintain and can be simply and quickly replaced, if needed.

Find out more about decentralised drive solutions with controlled frequency inverters in end-of-line packaging from NORD