#White Papers

Download now: Packaging industry white paper

Find out how you can achieve cost benefits of up to 50% in end-of-line packaging thanks to decentralised drive solutions with controlled frequency inverters.

Find out how you can achieve cost benefits of up to 50% in end-of-line packaging thanks to decentralised drive solutions with controlled frequency inverters.

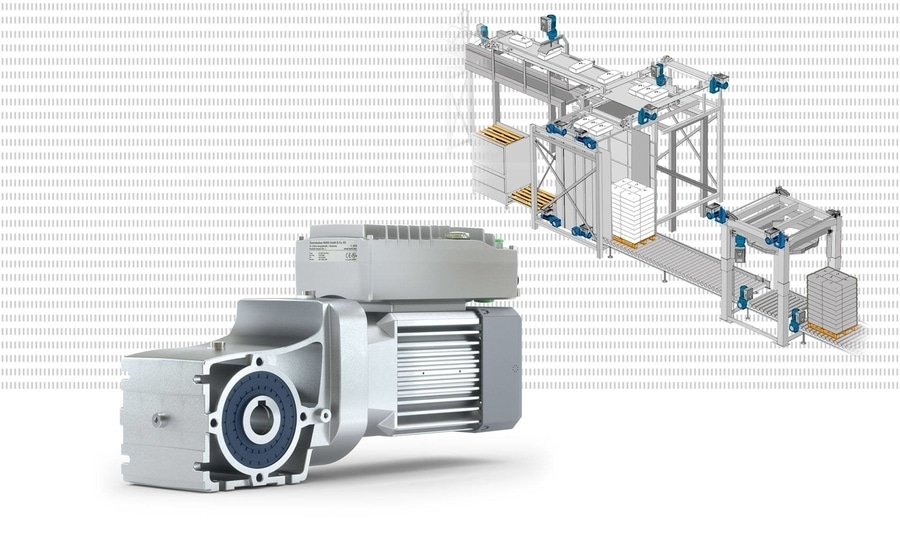

Drives with centrally controlled servo motors are commonly used in end-of-line packaging. However, in applications with large inertia or long movement distances – for example palletising, stabilising or handling – they are usually not mandatory. Decentralised drive solutions, for example with controlled asynchronous motors, are an efficient and economical alternative in this context. They achieve similar kinematic properties and, due to their higher internal inertia, ensure better regulation and motion control with heavy loads. The use of decentralised frequency inverters with “closed-loop control” also results in enormous cost savings. Depending on the system type and application, cost benefits of up to 50% are possible.

Read our white paper, to find out more about the use of decentrally controlled system solutions with asynchronous motors in end-of-line packaging.

Download white paper now