#Industry News

Our drives are part of the recipe

The kneading speed influences the consistency and flavour of a baked product.

The kneading speed influences the consistency and flavour of a baked product. In the baking industry, drive systems ensure the safe and variable control of this process. “The drive concept becomes part of the recipe”, says Jörg Niermann, Marketing Manager at NORD DRIVESYSTEMS. NORD, however, also supports the baking industry in further process stages.

With technical and industry expertise, the system supplier supports the baking industry by developing tailor-made drive solutions for all areas of the production process. This ranges from the mentioned dough processing, precise matching of dough feed belts and conveyor processes, metering and filling up to product and final packaging. The NORD modular products include drive components that are specially developed for the food industry.

Examples are:

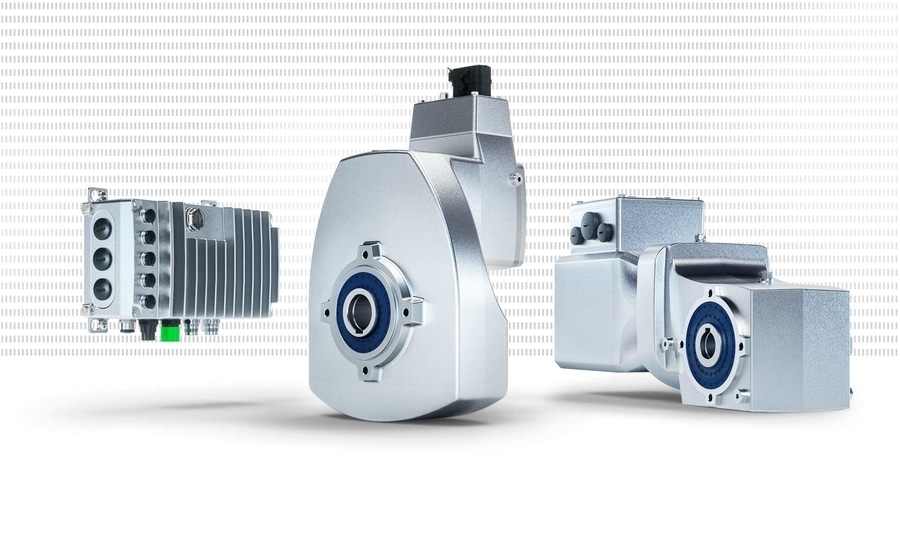

2-stage NORDBLOC.1® bevel geared motor with aluminium housing in an easy-to-clean wash-down version for conveyor technology applications

the integrated DuoDrive gear unit/motor concept with high-efficiency IE5+ motor and a single-stage helical gear unit in a compact housing

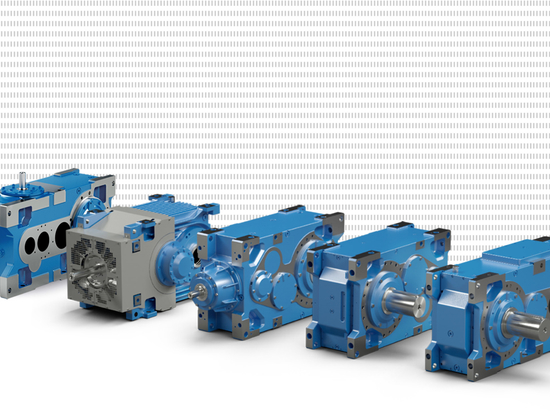

MAXXDRIVE® industrial gear units equipped with leak-free SAFOMI-IEC adapter and hygienic, fanless smooth motor for mixers and agitators

decentralised frequency inverters such as NORDAC ON+ or NORDAC LINK with a high level of pluggability and plug-and-play concept

NORDAC PRO SK 500P control cabinet inverter with USB interface for voltage-free parametrisation

“The baking industry requires low-maintenance, energy-efficient and durable solutions”, says Niermann. “With our industry expertise and the suitable products, we enable our customers in the baking industry to achieve highest standards.”