#Industry News

Overdimensioning is no longer necessary

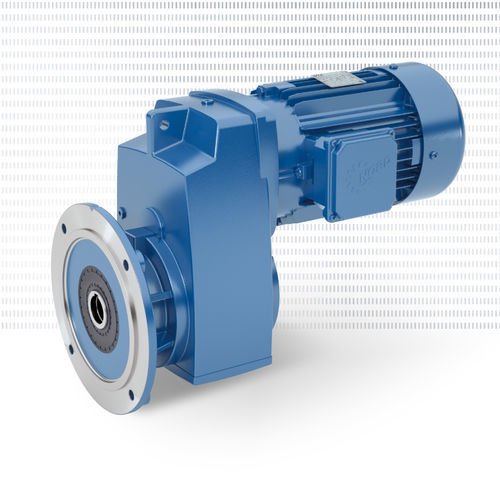

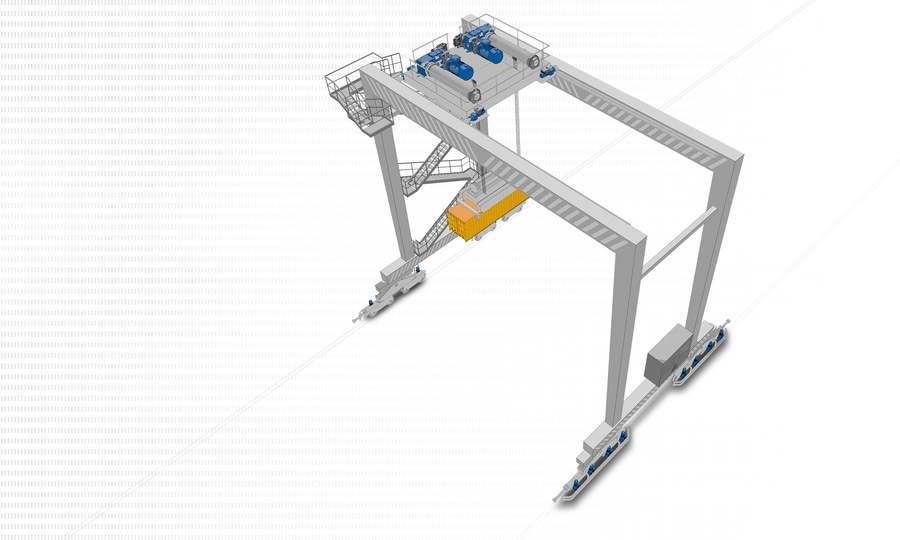

For different types of cranes and load ranges, NORD DRIVESYSTEMS offers properly dimensioned drive solutions from a single source.

For different types of cranes and load ranges, NORD DRIVESYSTEMS offers properly dimensioned drive solutions from a single source. For that, the company can rely on locations in more than 80 countries. In Poland, the specialist for hoisting equipment PROTEA relies on the crane & cargo competence of the complete supplier from North Germany.

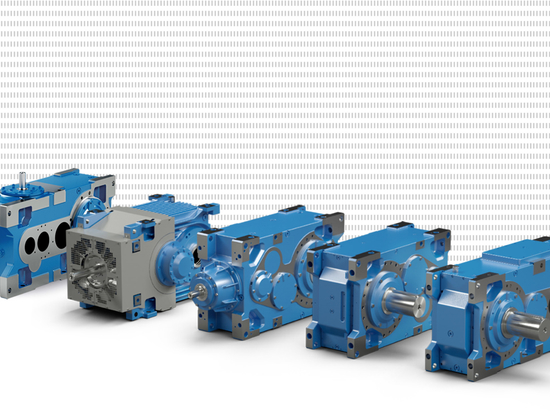

The Polish manufacturer PROTEA has been relying on drive solutions and services from NORD DRIVESYSTEMS for years. For its bridge cranes used, among other things, to transport bales of straw in biogas production, the company uses the MAXXDRIVE® industrial gear units . They can cover torque ranges of up to 282,000 Nm.

For PROTEA, several advantages of the NORD drive solutions for cranes add up:

In the lifting gear, the manufacturer uses a robust MAXXDRIVE® XD with a power of 18.5 kW.

These parallel gear units build on the proven UNICASE housing principle. They have been specially optimised for heavy loads.

The one-piece UNICASE housings impress with their durability and low maintenance costs. They have double seals ensuring smooth operation without leakage.

Due to the elongated arrangement of gear stages, the MAXXDRIVE® housing has a large centre distance, enabling a U-shaped drive design. Especially with lifting gear drives, the cable drum and the motor can thus easily be arranged on the same side of the gear unit.

The drives for cranes and trolleys also build on the MAXXDRIVE® industrial gear units with powers of 0.55 and 11 kW.

Thanks to its wide portfolio, NORD can assemble drive components precisely for the respective application requirements. Overdimensioning the drive is therefore no longer necessary.