#Product Trends

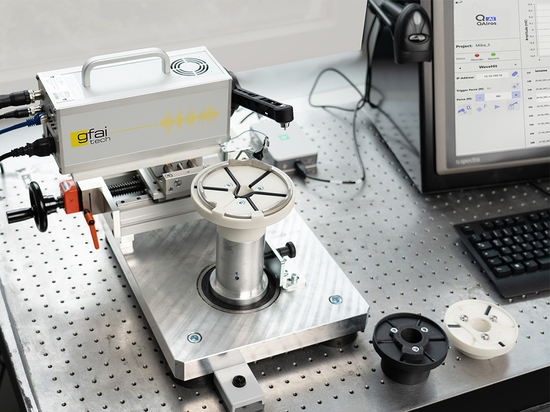

Impact hammer WaveHitMAX: the high-precision tool for quality assurance

WaveHitMAX provides new ways of mechanical excitation for structural dynamic applications

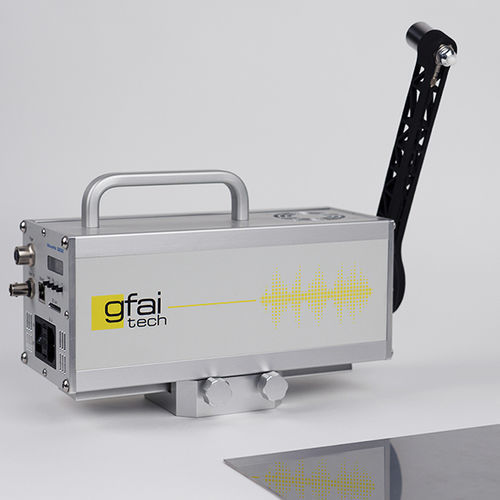

gfai tech presents the latest innovation in quality assurance: the WaveHitMAX MK2 modal hammer! The WaveHitMAX is known for its high precision in structural dynamic applications and is the first intelligent impulse hammer that guarantees fully automatic, reproducible single impact excitations. Say goodbye to tedious manual adjustments!

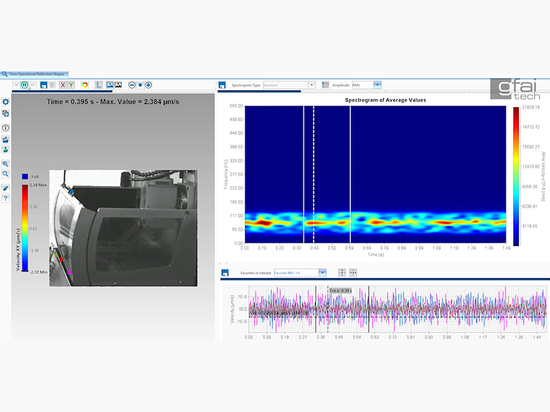

The new WaveHitMAX MK2 builds on the success of the original model and offers enhanced features. With the MK2, the type of signal output can be selected. In addition to the existing internal signal processing and analysis, it is possible to select the direct output of the force sensors at the signal output. This function has many advantages, such as a lower noise level of the measurement signal. In addition, further analyses of the signal can be transferred to an external data recorder and recorded, e.g. for FRF calculations, experimental modal analysis or coherence calculations. Furthermore, new possibilities for external calibration of the hammer are offered (DAkkS calibration, ILAC).

With two new operating modes - micro-impact mode for the excitation of structures with the lowest possible energy and manual mode for customised tests - the device is ideal for end-of-line tests for acoustic resonance testing.

Applications of the Impact Hammer WaveHitMAX:

• Experimental Modal Analysis: Accurately assess the vibrational properties of structures, essential for understanding dynamic behavior in fields like aerospace, automotive, and mechanical engineering.

• Acoustic Resonance Testing: Perform high-precision acoustic testing, allowing for effective defect detection and quality assurance in production processes.

• Condition Monitoring: Continuously monitor the health of machinery and structures by detecting changes in vibration patterns, crucial for predictive maintenance.

• Material Testing: Evaluate the durability and properties of materials under impact, helping to ensure that products meet industry standards and performance requirements.

• Impact Hammer Testing: Reproduce precise impacts for dynamic testing, delivering consistent, repeatable results that optimize testing procedures.

• Frequency Response Function (FRF) Testing: Analyze how structures respond to various frequencies, providing critical insights into system performance and helping to improve product designs.

Whether you're involved in research and development, production, or maintenance, the WaveHitMAX MK2 is the ideal tool for ensuring accuracy, reliability, and efficiency in a wide range of testing scenarios.

For more information, visit Impact Hammer WaveHitMAX at gfai tech website.