#Product Trends

Acoustic Cameras in use for the maintenance of wind turbines

Acoustic Pictures Identifying Noise Emissions

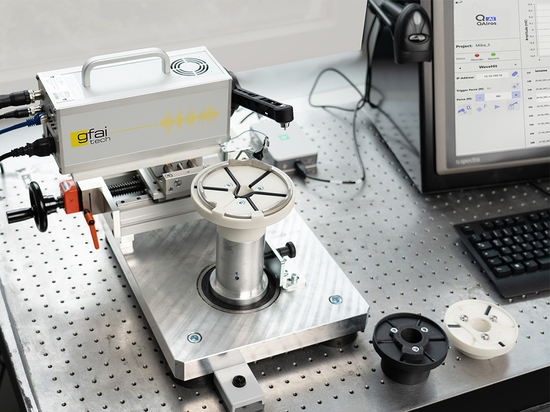

gfai tech presents an innovative solution for identifying defects in wind turbines more quickly and efficiently: the Acoustic Camera. With this technology, noise emissions that indicate potential operational faults can be precisely recorded and analysed. This leads to a significant improvement in the efficiency and reliability of wind turbines.

Targeted localisation of noise sources

Wind turbines consist of numerous mechanical and electrical components which, despite their robustness, can be affected by factors such as material wear, fatigue or external influences. Traditional inspection methods are often time-consuming and may overlook critical defects. With the Acoustic Camera, however, noises can be precisely located and analysed directly during operation, allowing maintenance teams to react quickly and avoid costly and dangerous failures.

Acoustic imaging

The Acoustic Camera utilises a large number of microphones arranged in a specific pattern to capture sound waves from the wind turbine. This creates an acoustic image or video that shows where the noise sources are located and how strong they are. Using this data, technicians can identify specific sources of interference and take measures to reduce the noise - be it by making adjustments to the rotor blades, the blade shape or by changing the operating sequence of the turbine.

The integration of the acoustic camera into maintenance strategies marks a significant step forward for the wind power industry. Operators can increase the efficiency of their turbines, minimise downtimes and reduce maintenance costs. An impressive example of this was provided by the Star48 AC Pro acoustic camera, which visualised noise emissions in various frequency bands at wind speeds of 7 to 10 m/s during a field measurement on a wind turbine. Within a few minutes, flow noise could be localised at the rotor blade tips and on the gearbox. Further information on these measurements can be found under ‘Free-field measurements of large objects during operation’.