#Product Trends

Gimatic Medical

Gimatic's challenge into the medical industry 4.0

Present for over 35 years on the automation market,Gimatic, a manufacturer of customized gripper solutions, has also the know-how for the medical industry 4.0.

The medical industry needs to be massively automated to be able to meet the ever-growing market demand. Speed, precision and reliability are key features in the medical industry.

For years, Gimatic has been providing customized automation components for a variety of laboratory applications. The standard products are modified to be able to meet the needs of the customer, through technical changes of the functions, adaptations of the interfaces of the speeds, force and gripping fingers.

In these difficult years Gimatic has committed itself to the fight against Covid-19, creating and offering its customers special EOAT, specifically designed to support the creation of protective masks for people who have worked and work on the front line for this health emergency.

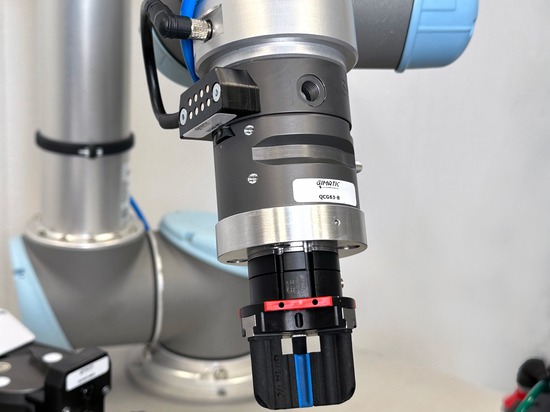

Thanks to Gimatic, everything is possible. This is demonstrated by the different tailor-made applications for customers, such as the GMP gripper for Denso Robotics, created for the production of medicines for anticancer therapies.

The solution fits perfectly among the ideal products for cleanroom production, i.e. in environments with a low content of suspended particles. This is possible due to the high level of cleanliness (ISO04) and the GMP level (Grade A / B).

The Gimatic MPPM1606-KIT-GMP Kit has been tested, together with the Denso Robot, by the IPA Fraunhofer Institute in Stuttgart in all conditions, in order to achieve the highest level of certification.

MPPM1606-GMP-KIT is composed of the linear electric parallel gripper with two self-centered jaws (MPPM1606), a silicone cover, special stainless steel fingers and ISO flange to be fixed directly on the Denso Robot.

The cover is made of Silpuran®Wacker FDA 21 CFR §177.2600 silicone.*, FDA /EHEDG approved and specially designed for medical applications. Thanks to the transparent cover, the reading of the LEDs of the internal sensors and the power status LEDs is immediate.

The accumulation of bacteria is achieved thanks to the smooth design surfaces and compatible with the cleaning procedure with hydrogen peroxide (VHP-H2O2) and UV ultraviolet rays.

The gripper drive is integrated and Plug& Play. For this reason, the gripper does not require any programming, thanks to the control electronics integrated into the body. The smart controlsystem, leads it to have a low power consumption, since at the moment when the gripper is in the socket, there is a power failure.

The toes of the gripper are easy to fix, thanks to the anti-rotation system and can be used on both sides, grasping from the inside out and vice versa.

The Gimatic GMP Kit is compatible with MPPM/MPXM/MPLM/MPLF/MPCF grippers. These grippers differ in stroke length and type of control, to meet the needs of different customers.