#Industry News

Guide to choosing the right electrical transformer containment bund

How to avoid human and ecological risks

While transformer container bunds may look simple enough, they are absolutely essential pieces of industrial equipment. They play a key role in preventing risks to human health and to the environment. Whether fixed or mobile, they serve to contain any possible leaks of dielectric oil, thus protecting against occupational and ecological hazards. They also enable compliance with Clean Water legislation. Choosing the right containment bund for your site depends on how it will be used, which determines the best materials to use and the best structural design.

Energized transformers

There are obvious safety issues involved in containing the hydrocarbons used in an energized transformer. In this case, extremely strict requirements apply in terms of the materials and structural design that can be used for the bund. The aim is to ensure that the electrical oils used are completely contained. In fact, not only is this type of fluid liable to leak out of the system, but it can also easily catch fire.

The standards in force in some countries, including NFC13-200 standard in France, require the use of a natural fire-extinguishing system for transformers over a certain power rating in the case of transformers installed outdoors, and for all indoor transformers regardless of power rating. Containment bunds with fire-extinguishing systems are designed to extinguish hydrocarbon substances that collect and may ignite in the bund, thereby reducing the risk of fire spreading.

De-energized transformers

If the transformer is not on-load, then there are not so many restrictions involved: the bund can be made of metal, concrete or flexible tarpaulin. In this case, the bund is needed solely to contain dielectric oil, not to extinguish fire. The use of a fire-extinguishing system is not a requirement. If the containment bund is intended for use during transportation or 'short-term' storage of the equipment, then it can be made of a flexible material or metal. Concrete would be much too heavy.

What is the best material to use?

It goes without saying that an energized transformer implies very specific containment issues. In general, a bund used for this purpose is installed for the long term. It may be made of concrete or metal. If you opt to install a metal containment bund, a modular design is recommended. A metal containment bund can also be installed more quickly than a concrete bund. It is the better option for systems deployed for relatively long periods.

The advantage with concrete containment bunds is that they are easy to custom build. They are extremely hard-wearing over the very long term. They are, however, subject to leaks. For that reason, concrete containment bunds must, to comply with the regulations, be sealed with a leakproof coating. This coating must be re-applied every ten years.

The requirements regarding de-energized transformers are not as strict, given that storage is only temporary. Depending on how long storage is planned for, a steel bund (if stored for longer than 1 year) or a flexible containment bund, the best option for short or medium-term storage, can be used. Flexible bunds are recommended for use when dismantling a transformer or refitting a substation, for example.

Certain regulations must be complied with when transporting a transformer equipped with a containment bund. The sides of the bund must be higher than those of a conventional bund, in order to prevent spillage while moving the whole assembly. The regulations applying to such convoys are set out in the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR). For most shipments that are not subject to the ADR, a flexible containment bund can be used. In all other cases, metal containment bunds designed specifically to conform with the ADR must be used.

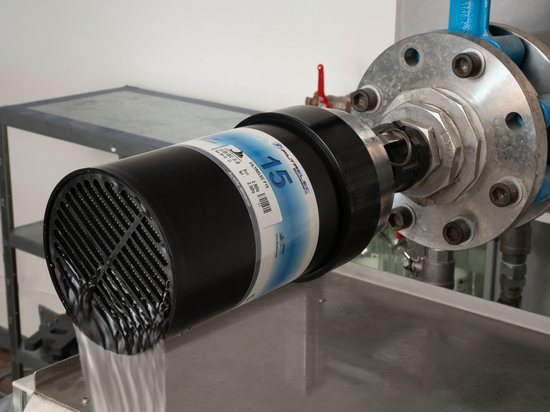

When choosing a containment bund for your purposes, be sure to set out your specifications in precise detail. Some bunds, not made of metal, are modular and therefore they come in certain standard dimensions. You can also opt for a custom-designed containment bund. All concrete containment bunds are in fact custom designed. All these different industrial solutions can be equipped with accessories to optimise their performance. For long-term storage, a containment bund, whether made of metal or concrete, can be fitted with a filter and drainage system. Get in touch with a professional to discuss all the different options available!

And if you have any questions, contact AKHELEC at: akhelec@akhelec.com