#Industry News

Higher calorific value than coal! The perfect home for used tires, a great transformation into alternative fuel!

Waste tire TDF alternative fuel has become mainstream abroad

Tires also have a lifespan. More than one billion tires are scrapped every year. More than 97% of them are discarded or piled in the open, which leads to serious environmental problems. They are also one of the largest and most challenging solid wastes in the world.

Waste tires are a composite composed of rubber, carbon black, chemical additives, fibers, steel wires, etc. The combustion calorific value is 25~50% higher than coal and 100~200% higher than wood.

It is an ideal substitute fuel. Therefore, tire alternative fuel (TDF) is one of the main ways to dispose of waste tires abroad.

PART 1 Waste tire TDF alternative fuel has become mainstream abroad

In 2020, the utilization of waste tires as alternative fuel in the United States accounted for about 58% of the total utilization, and among the utilization as fuel, about 51% were used in cement kilns and industrial kilns.

In Japan, the utilization of waste tires as alternative fuel accounted for about 68% of the total utilization from 2016 to 2018, and most of them were used in industrial kilns in power plants and cement plants.

Why will the preparation of waste tires into TDF alternative fuel become mainstream abroad?

In addition to the higher calorific value of waste tires than coal, TDF alternative fuel has the lowest carbon emissions among common alternative fuel types, producing more than 80% less carbon dioxide than coal. (The carbon emission factor of anthracite is 99.4kgCO2/GJ)

Moreover, the performance of waste tire TDF alternative fuel in industrial kilns is excellent. Each ton of TDF alternative fuel can replace 1.2 tons of standard coal on average.

Compared with 1,200 RMB/ton of standard coal, 800 RMB/ton of waste tires can provide Enterprises reduce costs and enhance the overall competitiveness of products.

Taking the industrial kiln of the cement kiln as an example, the substitution rates of TDF alternative fuels of different sizes in industrial kilns are also different.

The smaller the size, the better, but at the same time it brings high costs and low output, which is in line with the reduction of enterprises.

There are conflicting demands for coal in the province. Therefore, excellent TDF alternative fuel preparation technology will be the key to recycling, harmlessness and reduction of waste tires.

PART 2 TDF Alternative Fuel Preparation Technology

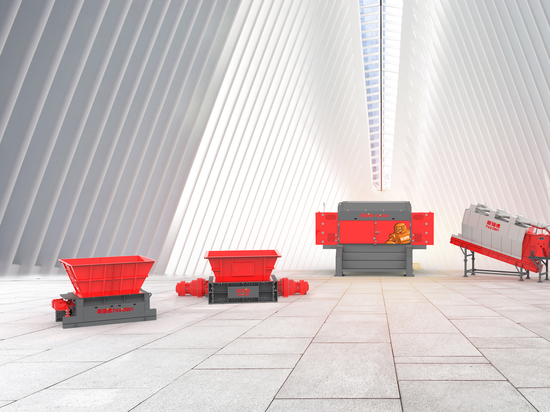

As one of the drafting units of domestic alternative fuel group standards, Harden has focused on and accumulated experience in the field of solid waste treatment for more than ten years.

The independently developed waste tire TDF alternative fuel preparation system has been optimized in terms of system structure. Secondary shredding, recycling screening and other process technologies are used to prepare waste tires into approximately 50mm TDF alternative fuel.

The overall operation is more stable, and the production capacity has reached 7 to 10 tons per hour.

In view of the physical characteristics of waste tires, Harden has specially designed a cyclic shredding form of "primary shredding-secondary shredding-screening". Through the double-shaft shearing shredder and high-quality alloy steel cutters, the materials are shredded in the second stage and then screened through the multi-angle power disc screen.

The materials that do not reach the required size will be transported to the first coarse In the crushing process, the second secondary crushing is carried out until the final material crushing size reaches the preset discharge requirements.

Such a design can make the final discharge size compliance rate reach 99%, and the discharge will be more uniform and delicate; in the practical application of industrial kilns, the fluctuation of combustion heat value will be more stable.

The entire system is fully automated and can be automatically adjusted and adapted according to each equipment and actual operating conditions to maximize production capacity and predict system abnormalities to ensure stable and safe operation of the system.

Currently, around the world, the paper-making, cement, chemical and steel industries are the main users of waste tires, consuming more than half of the waste tires every year. The SRF alternative fuel preparation technology used in this process is considered to be the best way to deal with waste tires.