#Industry News

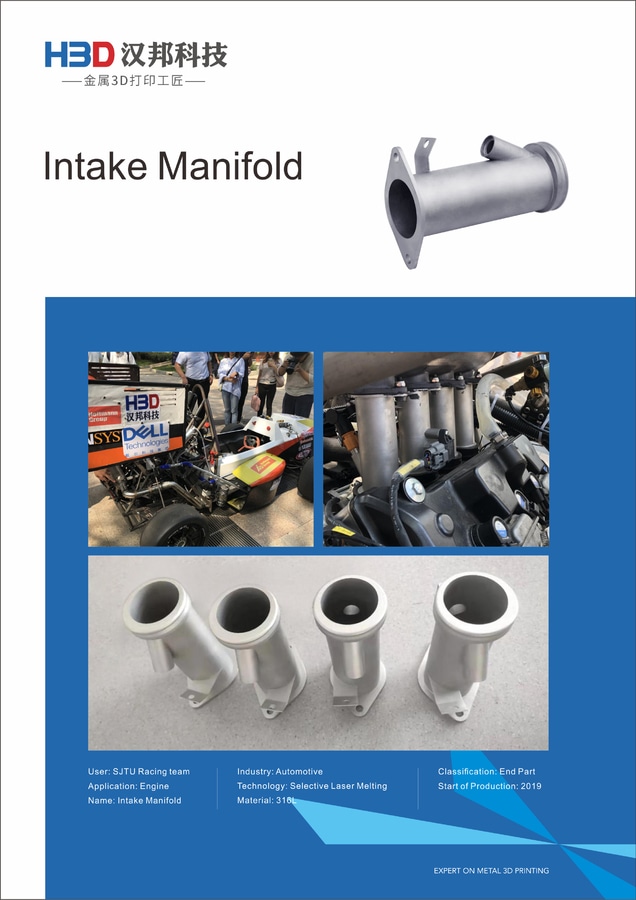

Intake Manifold-by HBD Metal 3D Printer

Automotive-HBD metal 3D printing application

Before using metal 3D printing technology, engineers first machined the main casing and then welded some of the side wall structures together by welding, so the entire fuel injection seat was particularly simple and cumbersome. Existing 3D printing processing features: (1) Adopting the design idea of 3D printing, the structural design has more possibilities, and finally achieves the purpose of lightweight design. (2) The previous manufacturing cycle was 2-3 weeks, and now it is shortened to one week, which speeds up the research and development. Future product design ideas: There are currently four fuel injection seats on a single car, and they are independent of each other. In the future, the design can be simplified, the four independent structures can be reduced to two or even a single integrated structure, and then directly manufactured by 3D printing, so that the structural design of the entire engine is more compact and lighter.

User: SJTU Racing team

Application: Engine

Name: Intake Manifold

Industry: Automotive

Technology: Selective Laser Melting

Material: 316L

Classification: End Part

Start of Production: 2019