#Trade Shows & Events

New generation of dosing machines with many innovations for highest process stability

Henkel shows precise seal foaming with Smart dosing cell at Fakuma 2023

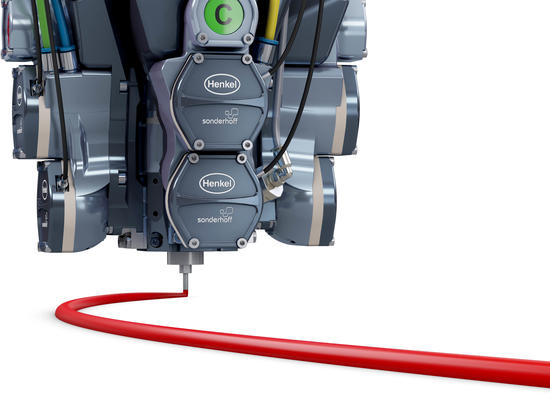

At Fakuma 2023 in Friedrichshafen, the world's leading trade fair for industrial

plastics processing, Henkel will present the Sonderhoff Smart-M dosing cell with the new DM

50x technology and the newly developed MK 825 PRO mixing head from October 17 to 21. The

dosing cell will be operated LIVE at booth no. 5109 in hall A5.

With the Sonderhoff technology portfolio, Henkel offers customized sealing, bonding and

potting solutions consisting of a wide variety of material systems, dispensing machines and

process automation from a single source.

The Sonderhoff Smart-M dosing cell exhibited at the trade show is the smallest compact class

for seal foaming, bonding and potting. All essential components of the dosing machine are

compactly arranged on the rear wall of the cell chassis. The material pressure vessels, which

supply the mixing head with the components of the 2K material systems via recirculation lines,

are located separately on a grid platform.

The dosing cells are available in two sizes: the Smart-M with a mixing head travel range of 500

x 600 x 250 mm (x/y/z) and the larger Smart-L with 1,000 x 800 x 250 mm (x/y/z).

The dosing cells can be configured differently. Both dosing cells are equipped with a lift door as

standard. Optionally, a rotary indexing table with 180° pitch is also provided for the Smart-M.

For the Smart-L, there is alternatively a sliding/shuttle table with two mounting plates for the

workpieces or a transfer belt circulating through the cell for part feeding and unclocking.

The Smart-M dosing cell will be shown at the trade fair with additional equipment options that

further increase process and dosing accuracy. These are the Nozzle-Control measuring unit for

checking the dosing nozzle, the Dosing Weight-Control, and the Air-Clean pneumatic nozzle

cleaning as well as high-pressure water rinsing of the mixing chamber.

The Smart-M and Smart-L dosing cells with DM 50x technology, which are used for a wide range

of applications, enable precise processing of 2K material systems and very high process and

dispensing accuracy. The sensors installed in the MK 825 PRO mixing head provide the user with

data on the formed-in-place (foam gasket) application process. They are used for precise

analysis, evaluation and control of the material application processes and are also used for

predictive monitoring and maintenance of wear parts.