#Industry News

HYDRAULIC SOLUTIONS FOR COMPLEX AND INDIVIDUAL CHALLENGES

BIG, BIGGER – HKS

HKS Dreh-Antriebe GmbH, located in Wächtersbach-Aufenau in the State of Hesse, has been developing, designing, producing and selling hydraulic rotary actuators, actuators, TiltRotators, rotary lift combinations, rack-and-pinion actuators and linear cylinders for 50 years. HKS was a pioneer in this industry, always driven by the right intuition. This is how HKS Dreh-Antriebe GmbH became one of the global market leaders.

All of the products, from concept and design to fabrication and assembly, are completely manufactured in Germany with “Made in Germany” quality in the extensive production halls of HKS Dreh-Antriebe GmbH. Depending on customer requirements, HKS specialists can develop prototypes, manufacture customized individual components and even produce entire series. Of course, this work also includes a clear service concept. As a system provider, HKS supplies not only rotary actuators, but also expert consultation and individual, customized solutions tailored to the respective, specific working area.

Hydraulic rotary actuators for test rigs

Hydraulic rotary actuators by HKS are used in many applications all over the world. Among others, they are used in various types of test rigs. What’s special here is that these actuators rotate at high speeds (up to 2,500 rev/min) to apply torque to a gear, for example, so that wear on these gears, among other characteristics, can be measured in endurance tests. Large automotive manufacturers also use HKS rotary actuators in their testing centers for fatigue tests on their gear units. These special actuators have undergone continuous further development and their technology is always state of the art.

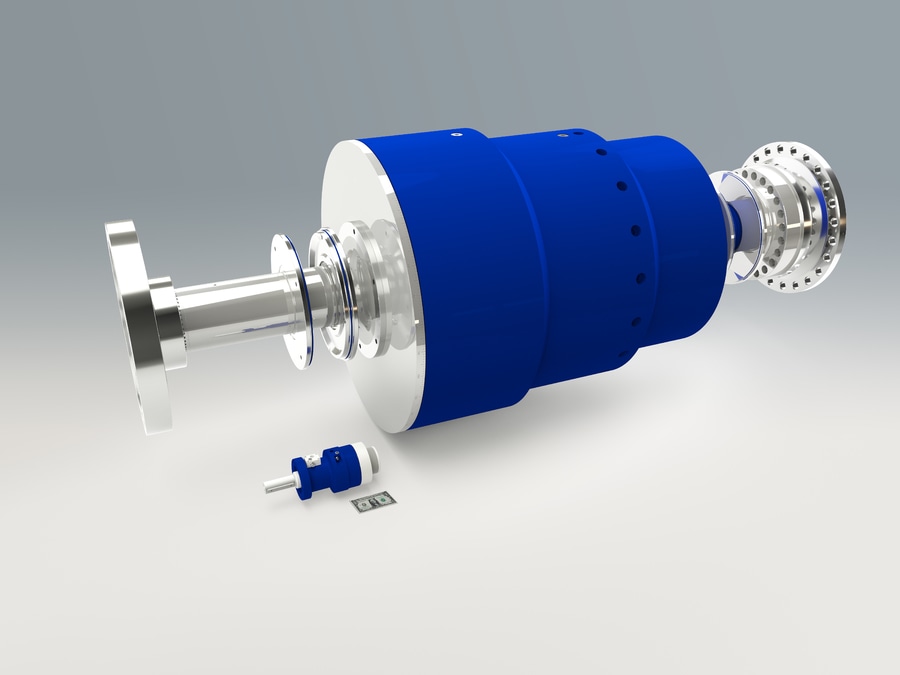

In 2020, HKS encountered an exceptional challenge which set new technical and manufacturing technology limits. In 2016, HKS had delivered a hydraulic rotary actuator of this type – the largest up to that time – for a test facility. With an outside diameter of 350 mm, weighing more 1,100 kg and providing a torque of 70,000 Nm, this actuator had already set enormous benchmarks. The rotary actuator met 100 percent of the requirements set for it. Based on these positive experiences, the manufacturer of the test facilities contacted the specialists at the HKS company again with a new challenge. In a new, “four-quadrant” test rig for high-performance gear units, the HKS rotary actuator is supposed to be mounted between an electric motor and a generator to compensate for frictional forces. This way, in the future, gear units and turbines can be tested in the megawatt output range, not just in the kilowatt range as before.

The largest hydraulic rotary actuator based on helical gear technology

This rotary actuator will rotate around its own axis at 3,500 rev/min, applying a torque of 80,000 Nm. In addition, it will have an angle of rotation of 270°, but will not exceed a length of 1,800 mm. A torque measuring device will also be integrated. Because the permissible length at 80,000 Nm is low, this actuator will have an outside diameter of just 680 mm and will weigh about 2,800 kg. This makes it both the largest and the heaviest industrial actuator based on helical gear technology ever developed and built. An exceptional challenge, even for the HKS production team at the Neukirch/Lausitz location.