#Industry News

The Hutchinson plant in Segré is certified ISO 50 001

The Hutchinson plant in Segré, specializing in the manufacture of dynamic sealing solutions and magnetic rings, obtained ISO 50 001 certification in January 2023.

Hutchinson plant in Segré, specialized in the manufacture of dynamic sealing solutions and magnetic rings, obtained ISO 50 001 certification in January 2023.

Obtaining ISO 50 001 certification is an essential step in the decarbonization plan for the plant. The target is zero emissions by 2040. This certification validates the implementation of an efficient energy management system to reduce the environmental impact of the factory's activities. This step is part of a global Hutchinson group’s approach.

The ISO 50 001 environmental standard is an energy management system that allows organizations to control and decrease their energy consumption. It also to reduces the carbon footprint and preserves natural resources by implementing sustainable and efficient energy practices.

This process involves identifying consumed power sources, implementing measures to reduce energy consumption, monitoring and evaluating results, and continuously improving practices.

To improve the energy usage management, sensors measure the electrical consumption of each equipment and infrastructure in real time. The analysis of the data allows for better management of machine heating periods.

Implementing sustainable and efficient energy consumption practices allows the site to reduce its carbon footprint by reducing greenhouse gas emissions.

In 2021, gas consumption for heating represented 21% of the plant's total energy consumption. In 2022, thanks to better heating management (lower room temperatures, modularity of heated areas, etc.) and a mild winter, gas consumption was reduced by 34% compared to 2021. "Heating now accounts for only 11% of our energy consumption," says Hélène Barguil, Health, Safety, Environment and Energy Manager.

The site is also going to set up a system for recovering heat from the machine cooling network via a heat pump to heat the water for the heating circuit. A reduction in gas consumption of more than 20% is expected.

"This certification proves the site's commitment to energy efficiency and reducing greenhouse gas emissions," says Jean-Remy Barrau, Plant Manager.

In addition to the ISO 14 001 and ISO 50 001 certifications, the plant has adopted a more global environmental approach:

• By implementing awareness among the 620 employees of eco-actions such as closing compressed air valves on weekends for equipment that is not in use or adopting soft mobility and carpooling.

• By reducing the environmental impact of products throughout the manufacturing process until delivery to customers by conducting life cycle analysis of products (carbon footprint assessment, use of recycled or bio-based materials).

About us:

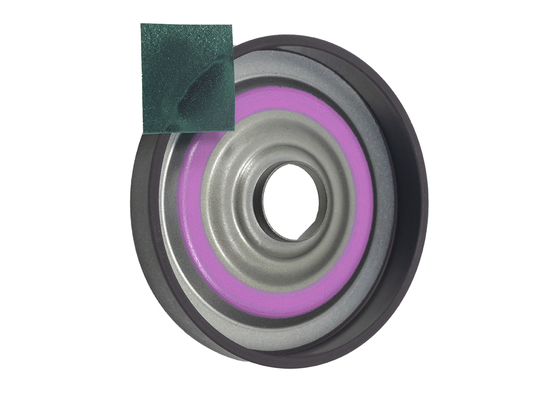

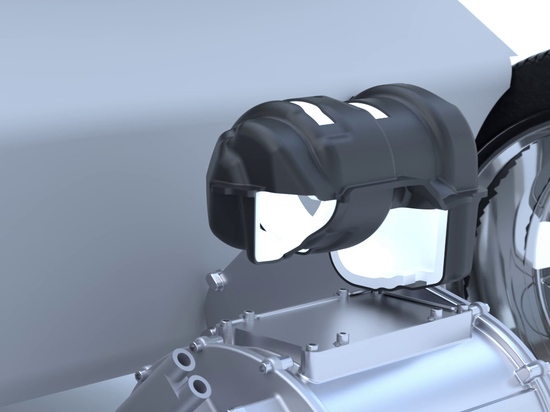

The Segré plant, based in the west of France, designs and manufactures standard and customized solutions for vulcanized rubber seals on a metal insert, such as shaft seals, pistons and bearing seals. From the definition of elastomers to the manufacture of finished products, the teams work with their customers to offer solutions adapted to the most severe applications in various industrial sectors such as automotive, aeronautics, defense, railways, etc.

The Segré plant belongs to the Precision Sealing Systems (PSS) activity of the Hutchinson group. With 23 sites in 19 countries, Hutchinson PSS employs nearly 6,000 people and has a turnover of more than €523 million.