#Industry News

Discover the post about SWR tape in the Flat sector

Woven roll material

The process of manufacturing friction materials is fundamental in numerous industrial applications, particularly in the production of components used in braking and transmission systems. One of the most common methods involves transforming the friction material from a roll form to a flat form.

Selection and Preparation of the Material: The process begins with the selection of suitable friction material, usually available in roll form. These materials consist of a combination of fibers, resins, and other particles that ensure high friction properties and wear resistance.

Unrolling the Roll: The roll of material is mounted on an unwinding machine, which unfolds it into a continuous strip. During this step, the material is inspected for any surface defects or inconsistencies.

Cutting and Trimming: Once unrolled, the material is cut into sheets of predetermined sizes. This process is carried out using cutting machines equipped with high-precision blades, ensuring clean and accurate edges.

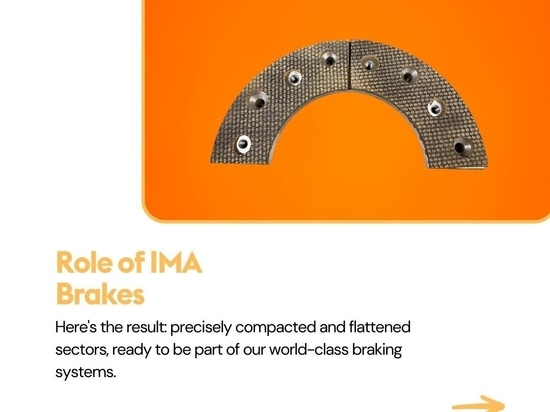

Vulcanization on the Metal Support: The sheets of friction material are then subjected to a vulcanization process. This step involves the application of heat and pressure to bond the friction material to a metal support, enhancing the strength and durability of the final product. Vulcanization creates a strong chemical bond between the friction material and the metal, imparting optimized mechanical properties to the piece.