#Industry News

Sival chooses Innova's Techlite Wrapping system

Sival chooses Innova's Techlite Wrapping system to automate its final packaging in Portugal

The building materials industry faces numerous challenges and requirements in the logistics and protection of cargo for export. Therefore, not only large production groups, but companies of all sizes are in the situation of finding packaging systems that ensure the stability of the loads and simplify and automate their processes. In this context, the Portuguese company Sival, which specializes in the manufacture of gypsum and other construction materials, chose Innova Group to automate its end-of-line processes and enhance the safety of its loads.

Innova Group responded to their needs with the recent installation in September 2024 of a packaging line with the innovative AWS arm wrapping machine at its main plant in Leiria. With over 75 years in the market, Sival is a Portuguese leader in building materials, specializing in traditional plasters, insulation systems, coatings for civil construction, and products for architectural rehabilitation. It stands out for its focus on sustainability, as gypsum is a recyclable and energy-efficient material, in line with the sustainability and efficiency objectives of Innova Group's packaging systems.

SIVAL'S CHALLENGE: AUTOMATION AND SECURING OF THE LOADS FOR EXPORT

Sival identified two key areas to optimize their production line. To enhance their operations, they first needed to improve the security of their export formats, ensuring that pallets arrived at their destination in perfect condition, regardless of transportation requirements. Secondly, they aimed to automate the stretch wrapping process, which had been performed semi-automatically until that point. This manual process was slowing down overall efficiency and posed challenges for productivity.

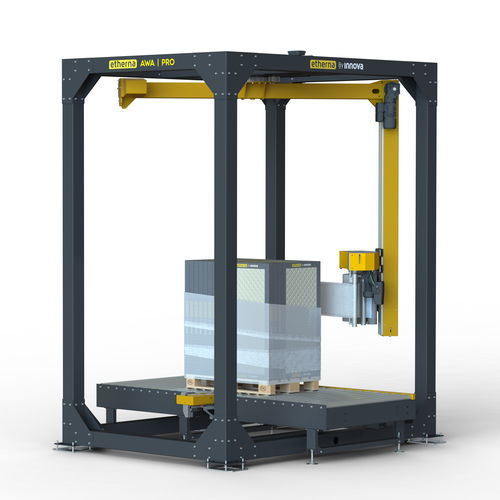

To respond to Sival's requirements, Innova Group proposed its new AWS Techlite arm wrapping machine, a solution specifically designed to automate the packaging of companies with medium production and adapt to the dimensions of the factory installation. This type of wrapping machine stands out for its lighter and more efficient design, which offers versatility to work with different sizes and types of loads while ensuring optimum wrapping. For Sival, a model featuring an automatic cover applicator was proposed to automate the process of fully covering and protecting gypsum loads during international transport.

THE SOLUTION: PACKAGING LINE WITH ROTARY ARM STRETCH WRAPPING

The Packaging line installed at Sival's Leiria facilities consisted of a wrapping system with its respective conveyors connected to its existing end-of-line.

1. AWS TECHLITE ARM STRETCH WRAPPER:

Innova's new Arm Stretch Wrapper allows loads to be wrapped safely and efficiently, thanks to the patented wrapping finish with twine tying. The Techlite model also provides greater system adaptability and flexibility at the customer's plant, as it is a lighter and more compact stretch wrapper structure. Thanks to the structure with fewer parts, maintenance is simpler and more efficient, resulting in higher productivity and less downtime.

Sival's project has also included an automatic top cover applicator add-on to protect the gypsum bag loads against external elements.

2. CONVEYOR LINE ADAPTED FOR SIVAL

The pallet conveying line has been designed to accommodate the entire pallet flow of the factory. It consisted of an infeed conveyor line connected and integrated with the palletizing line, which includes a pallet centering device before the stretch wrapper. After the wrapping system, there is an outfeed conveyor and a pallet accumulation line designed for Sival's load transport vehicles.

RESULTS FOR SIVAL: ENHANCED LOGISTICS AND OPERATIONAL EFFICIENCY

Following the commissioning of the Techlite arm wrapping machine, Sival has met their objectives of obtaining enhanced security for its export cargoes. This was one of the main challenges Sival was looking for.

The complete automation of the wrapping process has optimized operation times and significantly reduced human errors, improving efficiency and reliability at their end-of-line. Additionally, the new stretch wrapper has improved film usage by incorporating a film pre-stretching system that can stretch up to 350%, along with adjustable tension through a torque control system, optimizing the use of consumables. This aspect, along with the wrapper's energy efficiency, has contributed to the sustainability goals of the Portuguese company.

Sival has expressed its trust and satisfaction with the project and installation performed by Innova technicians. Carlos Pereira, Sival's Factory Manager, stated: “Thanks to Innova's packaging solution, we have made significant progress in protecting our shipments and modernizing our facility. This advancement is crucial for companies like ours to remain competitive in the international market.”.

Sergio Llidó, Innova Group's Managing Director, added: “We are proud to collaborate with leading companies such as Sival. This project emphasizes our dedication to providing innovative and efficient packaging technology globally that addresses the specific challenges of each customer.