#White Papers

The Risks of VOCs in Industrial Projects

Industrial projects can possess various hazards and risks, some of which can be delayed in remedying.

However, volatile organic compounds (VOCs) are a prime example that is often not immediately noticeable but can be dangerous.

VOCs are organic gases that seep out of some solids and liquids. While these compounds are common in nature, their concentrations can be up to 10 times stronger indoors, posing significant threats to worker health. Depending on the specific gas and exposure time, VOCs can lead to headaches, nausea, liver, kidney, and nervous system damage, and even cancer.

The first step in addressing these hazards starts with understanding where the biggest VOC risks occur, which is dependent on applications and industries VOCs can appear during processes.

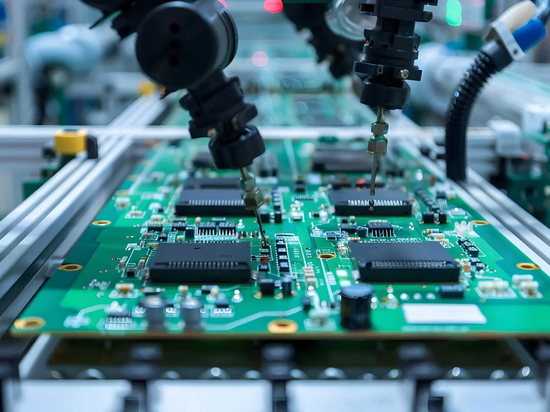

Manufacturing

Many VOCs come from raw materials used in manufacturing production, a process particularly prone to hazards. Paints and adhesives are some of the most common sources, as their processes versus daily use can be more hazardous to workers during production. Some common VOCs to watch out for include butane, benzene, formaldehyde, and methylene chloride. While small amounts of these chemicals may not have any noticeable health effects, manufacturing workers may be around them in far greater concentrations.

Supply Chain

Another source of industrial VOC risks is the supply chain. Even though a facility may not manage any raw materials that emit these compounds, they may be released by parts or products in transit. As a result, the workers who unpack, move, or otherwise handle these items may be exposed to high VOC concentrations. Packaging materials can also contain VOCs. Studies show that softer plastics like PVC and PE emit more prominent quantities of VOCs because of their porous nature. These more flexible materials also happen to be common in packaging products, so workers moving boxes around or unpacking shipments may be at a heightened risk. During long shipping times, some chemicals may seep out of products, especially at warmer temperatures, leading to VOC buildup before workers open these packages.

Building & Construction

Industrial businesses may also encounter VOCs through emissions from the facility itself. These compounds appear in common building materials like caulks, varnishes, and upholstery. Insulating foam and vinyl flooring may also contain dangerous chemicals that can seep out over time, leading to long-term exposure. VOCs typically don’t emit large concentrations from these materials, but industrial buildings undergo more strain. Because floors, walls and furniture in a manufacturing facility or similar property will see heavier use, they may emit more gasses. Employees working long shifts or putting in years of service are at a higher risk of exposure.

Mitigating VOC Risks

Once you know where the largest VOC risks are, you can take more effective measures to mitigate them. Start by running a VOC assessment by going over the materials used in your processes, production and application to see what VOCs workers face and in what concentrations. Utilizing technologies that incorporate the internet of things (IoT) to monitor in-air concentrations will provide more insight into exposure levels.

Next, ensure all workspaces are well-ventilated. Air cleaners often aren’t effective at removing VOCs, so it’s best to move these hazards out of working areas as soon as possible. Use industrial-grade fans and HEPA filters to ensure consistent airflow and move indoor airborne contaminants outside.

Educate employees about the dangers and signs of VOCs. If anyone notices symptoms like shortness of breath or eye, nose, and throat irritation, they should report it and step away from their work as soon as possible.

Finally, implement an effective gas detection system that incorporates the technology for connectivity to monitor various locations within the site and accurately measure the concentration of VOCs so workers not only rely on their senses. Be sure to continually monitor VOC levels to catch any concerning trends before they endanger workers.

VOCs can be difficult to detect, but they’re remarkably common. When you know about these hazards and where they come from, you can make more informed decisions about minimizing the related risks.

ION Science is a leading gas detection and prevention company offering a variety of wired, portable and personal solutions across a vast amount of applications. To find out more about products offered by ION Science for gas and leak detection, view our products page. For more information about VOC monitoring or if you have a question for us, contact ION Science today.