#Industry News

Hydraulic pump to driver adaptors

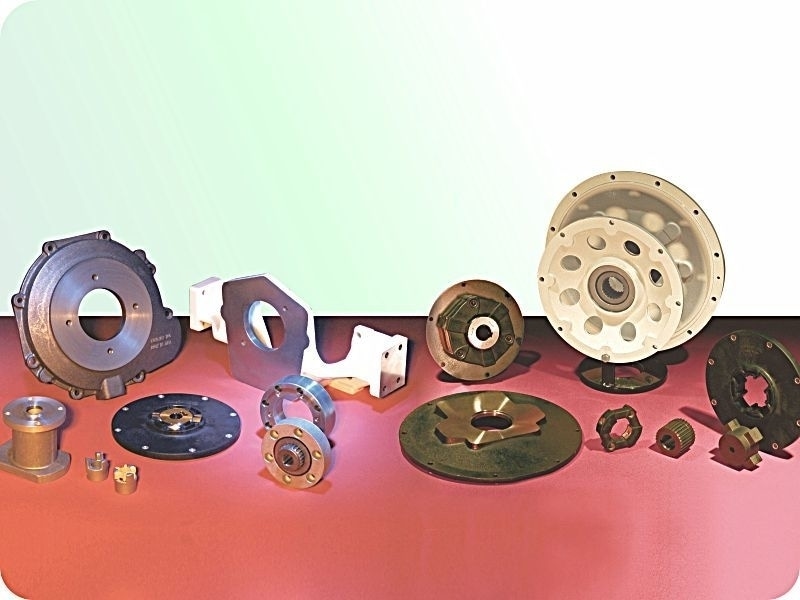

Allow close coupling of hydraulic pumps directly to the flywheel/flywheel housing of diesel engines, electric and hydraulic motors.

Designed primarily to allow the close coupling of hydraulic pumps to a variety of prime movers, such as diesel/petrol engines, electric, air or hydraulic motors, they can also be used in the connection from prime mover to alternative driven parts i.e. gear boxes, generators, water or vacuum pumps etc. An additional range of engine front PTO adaptors, which provide additional connection between the engine pulley and the driven part are also available.

The kit comprises of a bellhousing and flexible drive coupling that are fully machined to suit the driving and driven components. These can be to suit either shaft to shaft, flange (flywheel) to shaft or even flange to flange connections.

Getting the most out of your equipment will demand close integration between all components. In specifying jbj Techniques as your preferred supplier, you will have selected a company with the experience to specify, manufacture and integrate all of the diverse components that will ensure the best component combination for your application.

jbj's in house design team and manufacturing facility provide tailored solutions for your applications at competitive pricing and on-time deliveries.

Pump shaft alignment is key to preventing unnecessary wear and damage to the pump shaft seal and bearing. Improper alignment may lead to premature pump failure.

Axial misalignment can be caused by different tolerances or by thermal expansion of shafts and

components that the shafts are in contact with.

Radial misalignment can be defined as a measure of the offset distance between the centre lines of

the driving and driven shafts. This type of misalignment causes the highest stress due to the forces

involved.

Angular misalignment can be defined as a measure of the angle between the centre lines of the

driving and driven shafts, where those centre lines would intersect approximately halfway between

shaft ends.

Shaft misalignment is the result of displacement during assembly and operation and where machines

constructed with two radial bearings each are rigidly coupled causing high loads to be applied

to the bearings. Elastic deformation of base frame, foundation and machine housing will lead to

shaft misalignment which cannot be prevented even by precise initial setup alignment. Furthermore,

because individual components of the drive train heat up differently during operation, heat expansion

of the machine housings causes shaft misalignment. Poorly aligned drives are often the cause of

seal, rolling bearing or coupling failure. Alignment should be carried out by specialist personnel

in accordance with operating instructions.

Flexible shaft couplings are designed to relieve the effects of mechanical power transmission shaft

misalignment. Rigid shaft couplings are able to transmit higher torque than flexible shaft couplings due

to the cushioning effect of flexible coupling elements adsorbing some of the torque when using flexible

shaft couplings.

www.jbj.co.uk/couplings.html#driver-to-driven

Also to be considered are unwanted torsional resonant frequencies in the system which can quickly cause damage to components in the drivetrain and reduce system life and performance.

Improper pump installation can lead to premature failure, increased maintenance costs and reduced production levels of final product.

Jbj Techniques can advise on the correct installation of hydraulic pumps into Industrial / mobile / marine / machine tool / agricultural / offshore industries and can specify complete driveline systems from their extensive range of components which are available from stock or manufactured to order, albeit simple or complex, standard or bespoke.

For further information: www.jbj.co.uk/hydraulic-adaptors.html

All components can be machined in-house at jbj Techniques to customer specification to suit many applications.

www.jbj.co.uk/drive-line-harmony.html

Team of highly qualified and experienced engineers to assist in the correct specification of mechanical power transmission and fluid power components. Telephone: +44 (0)1737 767493 or email info@jbj.co.uk