#Industry News

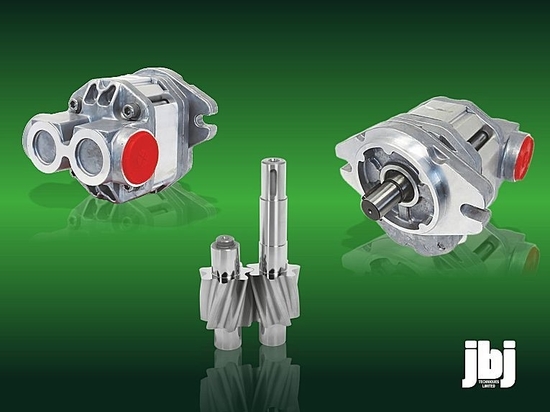

Low Noise, Helical Gear, Fluid transfer pumps (FTP)

Ideal for low-pressure, low viscosity lubrication applications such as fire-resistant fluids.

The low noise, high efficiency, low pulsation, fluid transfer, helical gear pump reduces noise level by an average of 15 dBA.

This FTP helical gear pump is the ideal solution for low-pressure lubrication applications where low-viscosity fluids are required, such as fire-resistant fluids.

Displacement from 7cc/rev to 87cc/rev with volumetric efficiency levels of 90 - 95%, compared to screw pumps at approximately 66%, and double contact gear pumps at around 87%. This helical gear pump performs at these levels even at low rotational speeds of 200 rpm therefore requiring less expensive connected running gear.

Typical applications include large lubrication systems, lubrication of the guides of machine tools, and the lubrication and cooling of tools themselves.

Fire-resistant fluids are used whenever there is a possibility that a hydraulic fluid (also used for lubrication) may encounter a source of ignition, such as the surface of very hot equipment. Fire-resistant hydraulic fluids are specially formulated so they are more difficult to ignite and do not propagate a flame from an ignition source.

There are several types of fire-resistant fluids and they are generally classified as follows: oil and water emulsions, water-polymer solutions, and anhydrous synthetics. More specifically, the International Standards Organization (ISO) further classifies these fluids as follows: HFAE – oil-in-water emulsions, typically with more than 80% water content; HFAS – synthetic aqueous fluids, typically with more than 80% water content; HFB – water-in-oil emulsions, typically with more than 40% water content; HFC – water polymer solutions, typically with more than 35% water content (also known as glycol solutions, polyalkylene glycol solutions or water glycols); HFDR – synthetic anhydrous fluids composed of phosphate esters; and HFDU – synthetic anhydrous fluids other than phosphate esters. Examples include polyol esters and polyalkylene glycols.

The only fire-resistant fluids that are completely incompatible with these gear pumps are the HFDR type; for all the others, it is possible to obtain a configuration that makes them compatible. To avoid fast wear of the sliding contact parts, FTP pumps can be supplied, depending on the type of application with bronze or bronze/PTFE thrust plates. These FTP helical gear pumps are available in versions with or without a relief valve built into the cover, and maximum working pressure is 50 bar. The gear pumps have very high specifications for rotation speed and viscosity range. FTP pumps are available with both unidirectional, clockwise or counterclockwise rotation, and all commercial versions of standard gear pump.

For further information use the link below right . . .