#Industry News

What is the best machine for car floor mat cutting?

CNC cutting machines for car floor mats soon emerged. Its faster cutting speed and higher precision better meet today's market needs.

In recent years, with the improvement of living standards, family cars have become more and more popular. For more and more car owners, cars are now not only a means of transportation but also a means of transportation. They place higher demands on higher quality performance and indoor environment.

Therefore, as an indispensable part of car interiors, the car floor mat market has grown exponentially in recent years. More and more car owners consider floor mats as the first thing they buy after buying a car. It can be seen that the automobile floor mat production industry has great room for development.

car floor mats

In addition to the huge market potential, the automotive floor mat industry also has a huge feature: low barriers to entry. You can start a car floor mat factory by preparing raw materials, cutting equipment, and sewing machines. The technical requirements for cutting and sewing in this industry are also straightforward and can be fully mastered in one or two days.

Such a good market prospect has led many investors to turn to the footpad production industry. They try to find the right cutting machine.

CNC-cutting machines for car floor mats soon emerged. Its faster cutting speed and higher precision better meet today's market needs.

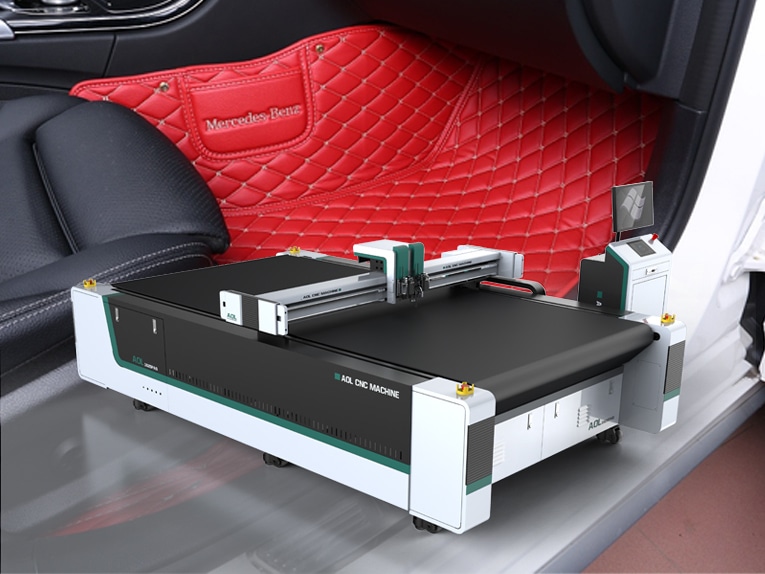

Car mat cutting machine

To save costs, many investors did not choose CNC cutting machines for car floor mats at first, but chose laser cutting machines. However, after several years of observation, laser cutting machines have major problems in cutting soft materials.

First of all, the high temperature generated by thermal cutting will scorch the material, causing black edges and burnt edges, which affects product quality.

Secondly, thermal cutting produces a lot of smoke and unpleasant odor, which is not environmentally friendly.

Therefore, laser machines are very suitable for cutting hard materials such as metal and wood, but not for cutting flexible car mats.

Because of the Achilles' heel of laser cutting machines, a machine more suitable for cutting soft materials is gradually being promoted, that is, CNC vibrating knife cutting machines.

The vibrating knife cutting machine is not only superior to the laser cutting machine in terms of cutting speed and accuracy, but also uses the cold cutting method of the blade to cut, which is more environmentally friendly, does not produce odor and smoke, and does not destroy the characteristics of the material itself.

The vibrating knife cutting equipment can also replace the cutter head and support different cutting tools such as circular cutters, pneumatic cutters, vibrating cutters, CNC milling cutters, brushes, etc., with more comprehensive functions. It can be widely used for cutting car mats, sponge foam, EVA, PVC, carton packaging, multi-layer fabrics, leather, and other materials.

AOL CNC vibrating knife cutting machine adopts the blade cutting method, eliminating the environmental problems caused by traditional laser cutting. The supporting intelligent typesetting system and imported servo motor shorten the cutting time and significantly improve the cutting efficiency. Moreover, the high-frequency vibration cutting method makes cutting more accurate and the cutting quality is better, thereby enhancing the overall competitiveness of the product.

A high-quality vibrating knife-cutting CNC machine will make you stand out in a world full of potential and increasingly fierce competition