#Industry News

How to apply CNC blade vibrating knife cutting machine in the shoe, hat and luggage industry?

With the rise of consumer demand, the processing technology of cutting machines used in shoes, hats, bags, and fabric accessories is becoming more and more extensive and diversified.

With the rise of consumer demand, the processing technology of cutting machines used in shoes, hats, bags, and fabric accessories is becoming more and more extensive and diversified.

With the improvement of living standards and changes in aesthetic standards and the pursuit of personalization, orders in the shoe, hat and luggage industry tend to be multi-variety and small batch. In order to meet the production needs of these orders, the entire industry urgently needs more systematic production solutions.

Traditional cutting method:

Manual cutting

Round knife cutting

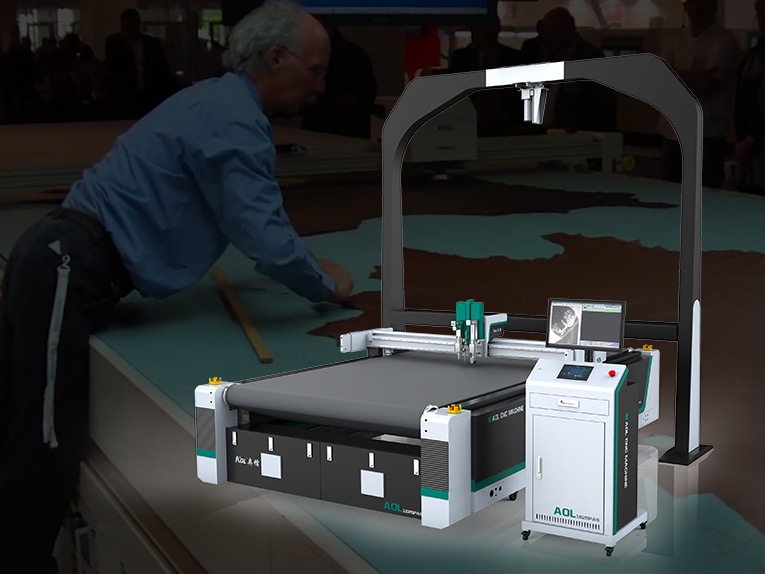

The CNC cutting machine approach enables companies to better adapt to future customer needs for small orders, diversified styles and higher quality requirements. AOL cutting machine is suitable for cutting fixed width artificial leather, composite plush, mesh, laminate fabric, printed fabric and other flexible fabrics.

AOL luggage industry cutting machine has rich industry experience in cutting all kinds of flexible materials. After years of independent research and development and improvement of software and hardware, it has brought a variety of cutting solutions to the shoe, hat and luggage industry, which can systematically improve the industry's cutting technology and Processing efficiency.

Difficulties in shoe cutting:

During the processing of shoe leather, traditional processing methods have difficulties such as the need for customized molds, high labor requirements, high costs, easy wear of molds, and difficulty in producing some patterns.

Problems with traditional shoemaking processes:

Craftsmanship issues: Due to the small size of shoes, the space for creating beauty is limited, and more advanced fine equipment and technology are urgently needed to innovate the appearance.

Quality issues: Most processes are completed manually, and product quality varies due to human factors, making it difficult to maintain stability.

Efficiency issues: Production efficiency is low, mainly relying on a large number of ordinary workers to complete orders according to flow, and there is an urgent need to complete intelligent transformation.

Cost issues: The large amount of labor in the production process causes high management costs, and excessive manual labor also causes waste of materials.

Personnel issues: The factory cannot find young people, many links rely too much on teachers, and many equipment in the production process pose personal safety risks.

The application of AOL CNC shoe bag cutting machine in the field of shoemaking can realize shoe upper hollowing, marking, cutting, lining, midsole plate and other auxiliary material cutting, sole and footbed cutting, and perforation, covering almost all material cutting applications. Just in the selection of equipment and functions, shoe manufacturers have their own needs and priorities.

In the shoemaking industry, cutting technology is commonly used for cutting leather uppers and hollowing out patterns. After setting the graphics on the computer, the set graphics will be cut out, special patterns will be hollowed out, and exquisite patterns will be punched on the leather fabric, bringing people a new sensory experience.

The consumption of personalized fashion clothing in the Internet era corresponds to the production of small batches and multiple styles. A style may be one piece or twenty pieces, with various categories.

To achieve a small-batch, multi-category, and quick-response production process, AOL CNC large vision camera digital cutting machines can be used to achieve material cutting quality and efficiency during the production process.

Nowadays, fewer and fewer people make and wear cloth shoes. Thousand-layer cloth shoes are breathable, soft and comfortable on the feet. Many individuals and companies began to produce cloth shoes and strive to open up the market.

In order to adapt to the market, cloth shoes should look exquisite and be easy to wear. Therefore, we need to improve our craftsmanship, choose wear-resistant and durable fabrics, increase varieties, and diversify designs and colors. Also, pay attention to the style of your shoes.

Applicable industries