#Industry News

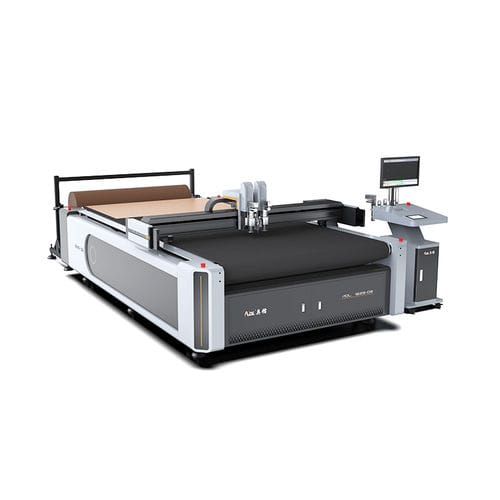

CNC cutting machine for tarpaulins

Do you know how to cut tarpaulins commonly used in the tarpaulin industry?

One innovation making waves in tarp manufacturing is the use of computer numerically controlled (CNC) cutting machines. These high-tech machines have revolutionized the way tarps are cut, delivering unparalleled precision and efficiency.

Usually in the tarpaulin industry, the materials are wide and long large materials. In order to meet the cutting needs of these large materials, we at AOL can customize equipment of different sizes according to different needs.

Why AOL is a good choice:

Ideal for Large Jobs: These machines are perfectly sized to handle a variety of materials and large graphics within the industry.

Precise feeding: A dedicated feeding system ensures precise and continuous feeding and reduces errors.

Speed and efficiency: Round and oscillating blades cut at speeds up to 2000mm/sec to get the job done quickly.

Anti-Deflection Feature: Our CNC machines minimize material drift and maintain accuracy, which is critical for large graphics.

Tool Versatility: These machines can use a variety of tools, such as round blades and oscillating blades, ensuring precise customization.

CNC (Computerized Numerical Control) tarpaulin cutting machine with digital knife is a special equipment designed for precision cutting of various materials used in tarpaulin production and related industries. Cutting tarps accurately and efficiently is critical to industries ranging from manufacturing to outdoor gear production. CNC digital tools simplify this process.

CNC cutting machines can cut tarps using various types of digital cutters depending on the material and required cutting accuracy.

Oscillating Knife: This type of knife vibrates rapidly back and forth while cutting. It is suitable for cutting soft and semi-rigid materials such as tarps, fabric-wrapped panels and acoustic foam. The oscillating motion ensures clean, precise cuts.

Round Knife: A round knife has a round blade that rotates as it cuts. They effectively cut curves and complex shapes in tarp materials.

Marker: Marker is an important accessory when cutting tarpaulin with CNC digital knife cutting machine. It helps streamline the cutting process, improves accuracy, and ensures the final tarp product meets the required specifications.

CNC tarpaulin digital knife cutting machine is like a versatile teacher in the field of tarpaulin production. It works its magic on a variety of materials used to make these basic covers and outdoor gear. Let’s take a look at some of the main materials this machine can handle expertly:

Tarp Fabric: Whether it’s heavy-duty PVC coated tarp, sturdy canvas, or any other fabric, CNC machines can precisely cut it to create tarp sheets and products.

Vinyl: Vinyl is commonly used for tarp applications, but it can’t compete with the precision cutting capabilities of CNC machines.

Canvas: For those heavy-duty tarps, a CNC cutter can handle canvas materials smoothly even if you are working on a project with complex designs.

Polyethylene (PE): PE tarps are known for their durability and can be easily cut by CNC machines.

Polypropylene (PP): Lightweight and moisture-resistant, CNC machines can cut PP materials with precision.

Using a CNC digital knife cutter significantly simplifies the tarp cutting process, ensuring precision and consistency in the end result. Whether you're making custom outdoor gear or working on an industrial application, this method can improve the efficiency and accuracy of your tarp cutting task.