#Industry News

How to choose the most efficient cutting machine for cutting synthetic paper?

This article will reveal the disadvantages of cutting synthetic paper and help you better understand, use and cut synthetic paper.

With the development of technology, the application of synthetic paper is becoming increasingly widespread. However, do you know the disadvantages of synthetic paper decoupage? This article will reveal the disadvantages of cutting synthetic paper and help you better understand, use and cut synthetic paper.

Advantages of synthetic paper:

1. Lightweight and durable: Synthetic paper has the advantages of being light in weight and easy to carry, and is suitable for various occasions.

2. Environmentally friendly and harmless: Synthetic paper is made of non-toxic and environmentally friendly materials and will not cause pollution to the environment.

3. Various colors: Synthetic paper comes in rich colors and can be customized according to needs.

4. Soft texture, strong tensile strength, high water resistance, light resistance, cold resistance, resistance to chemical corrosion, and good breathability

Disadvantages of synthetic paper cutting:

1. Easy to scratch: Synthetic paper is easy to scratch when cutting, which affects the appearance.

2. Edge cracking: The edges of synthetic paper are prone to cracking after cutting, affecting its strength and durability.

3. Improper operation may cause safety problems: When cutting synthetic paper, improper operation may cause safety accidents.

Practical tips:

1. Choose the right cutting machine

First, you need to choose a machine suitable for CNC cutting synthetic paper. Generally speaking, power is an important reference option when choosing a cutting machine. Make sure the power of the machine can meet the cutting requirements to avoid incomplete or excessive cutting due to insufficient power.

2. Ensure the quality of materials

The quality of cutting synthetic paper directly affects the final finished product. Therefore, when choosing materials, be sure to ensure their quality. Choose products produced by regular manufacturers to ensure the flatness and durability of the materials.

3. Cutting depth and speed

During the cutting process, the depth and speed of the CNC cutting machine are adjusted according to the thickness and texture of the material. Generally speaking, cutting too deep or too fast can cause material damage. Therefore, a trial cut should be made before cutting to determine the best cutting parameters.

4. Avoid over-cutting

Over-cutting creates waste and increases costs. Therefore, when cutting, the size and shape of the cutting should be controlled to avoid unnecessary waste. At the same time, we must also pay attention to observe the situation during the cutting process and adjust parameters in time to ensure cutting accuracy.

5. Keep your work area tidy

CNC cutting machines will produce paper scraps during the cutting process. Keeping the table clean in a timely manner can ensure cutting efficiency and extend the life of the cutting equipment.

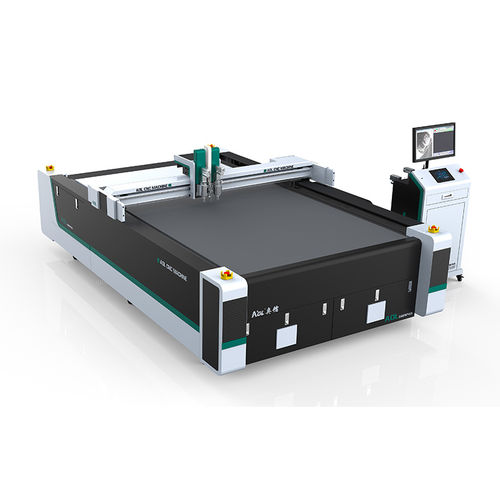

Here we recommend the AOL CNC synthetic paper cutting machine, please watch the video below to learn more!