#Industry News

CNC equipment for cutting marine fabrics

What features should a nautical fabric cutting room have? Versatility: Can cut different types of materials of different weights Flexibility: adaptable to more or less intensive production volumes

Due to their high-performance properties, composite materials are widely used in the marine sector, but their use in the production of hulls, decks and ship superstructures requires special precautions.

One of the links that determines the results is undoubtedly the cutting process. In the field of nautical fabric cutting, companies must set up cutting rooms according to certain techniques in order to achieve satisfactory results in terms of product quality and cost-effectiveness.

What features should a nautical fabric cutting room have?

Versatility: Can cut different types of materials of different weights

Flexibility: adaptable to more or less intensive production volumes

Speed: Reduce processing time for marine fabric cuts. Multi-layer cutting can greatly help reduce the time required, as long as it does not put undue stress on the tissue

Accuracy: Every cut must be calibrated and ensure millimeter accuracy

Different Types of Blades: Any good cutting room must have a variety of blades, maybe even ones tailored for each specific project

Automatic or manual cutting of nautical fabrics?

In addition to speed, automated cutting systems dedicated to marine fabrics offer two important advantages: The first is a 15-20% reduction in waste by eliminating inevitable errors in automated processes. The second is the repeatability of parts. In fact, the automatic cutting machine can ensure that the cloth is cut to the exact same size, which is impossible to achieve by manual cutting; this greatly improves the final quality of the product.

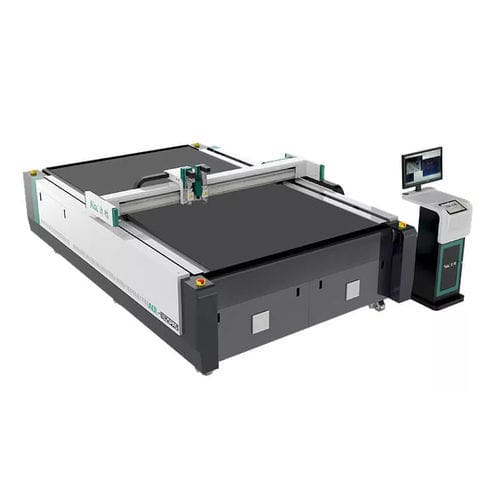

At AOL CNC, the focus on precision extends to the cutting of all types of fabrics, including the delicate and high-tech materials used in demanding industries such as aerospace, aviation and automotive. AOL CNC’s cutting machines specialize in the production of composites and fabrics for marine and marine applications and excel at shearing fiberglass or carbon fiber reinforced fabrics (even multiple layers). The versatility of the cutting machine extends to biaxial or multiaxial fiberglass and carbon fiber mats of varying weights, with AOL CNC’s machines demonstrating their ability to handle technically complex materials.

AOLCNC's marine fabric cutting machines are specially designed to perfectly cut the complex and demanding materials used for boat and yacht mats. Our machines are designed for complex materials such as PVC eco-leather, Teflon-treated Alcantara, polyurethane and polyester of different densities, ensuring millimeter accuracy. AOLCNC's cutting machines are ideal for fabrics in the luxury industry that require fine hand stitching, and are tailor-made to meet the challenges of handling these demanding materials.

Designed for cutting marine fabrics and composites, our cutting equipment is an automated conveyor cutting system that excels in precision and efficiency, even in multi-layer cutting. Suitable for large shipyards and subcontractors specializing in composite lamination, the AOLCNC deftly handles multi-axis mats and fabrics, setting new standards in precision and efficiency.