#Industry News

Mistakes that customers make when choosing vibrating knife cutting machines

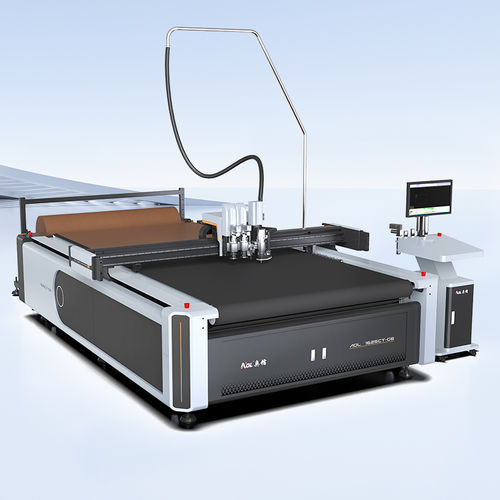

vibrating knife cutting machines

Size and machine specifications

Pursuing too big or too small is not the best choice. Choose according to actual needs. If it is too small, it cannot meet the processing needs; if it is too large, it will require more installation space and transportation costs. When purchasing a machine, you must first understand the cutting speed, depth, cutting area size, and compatibility with different materials.

One thing that must be noted is that when the overall width of the machine is greater than 2.3 meters and exceeds the width of the container, the machine will be disassembled for transportation. After receiving the machine, you need to assemble it.

Therefore, try to choose the size of the standard machine, especially the width (1600mm), unless you need a larger machine to meet the processing of ultra-wide materials.

Pursue multiple functions of one device

While versatility is great, cramming all your tools into one machine not only increases the price, it also squeezes your workspace and complicates operations.

We recommend that customers make reasonable choices based on their own processing needs, as long as they can meet your processing needs. Unless you need to meet very extensive processing needs, then you can communicate with us in detail and add more processing tools cautiously.

Pay attention to cutting height

Excessive pursuit of cutting height is not good. When purchasing a machine, some customers mistakenly believe that the higher the machine can process, the better. This is actually wrong. It is best for customers to choose the feeding height of the machine according to their own processing needs because when the feeding height of the machine becomes higher and higher, it means that the machine will be affected by the distance between the tool and the platform when cutting thin materials, leading to failure.

If the material you are processing has a relatively large span, you can tell the equipment manufacturer the material you are cutting and the specific specifications. The manufacturer will make reasonable configurations according to the needs to ensure that every thickness can be cut perfectly!

Does the manufacturer provide trial cutting and factory visits?

Trial cutting is a good and intuitive effect display, which allows customers to more directly see the cutting effect and the entire operation process of the equipment. But the real test is whether it can continue to deliver precise cuts over time. The difference between a good machine and a bad machine is not whether it can cut, but whether it can maintain high accuracy for a long time. It is important to know whether the equipment will be tested before leaving the factory!

Cutting equipment price

Equipment from different manufacturers may look the same, but their prices vary greatly. Why is this? I think I have heard enough of "you get what you pay for", but what I want to say here is that you have to believe what you see with your eyes but don't limit yourself to what you see! If you want to examine the real differences between the two machines, you have to know everything about it. For example, the craftsmanship of the bed, the quality of the accessories, the transmission structure, the after-sales service provided by the installation process, etc. Remember: only stable machines can help customers continue to create value.