#Industry News

What is the difference between a digital cutting machine and a laser cutting machine?

What is the difference between a digital cutting machine and a laser cutting machine

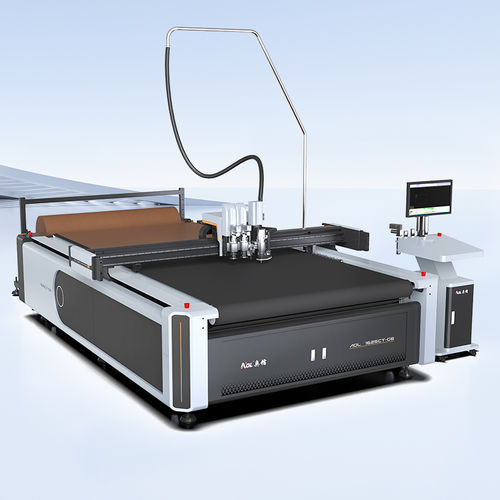

Now in the material-cutting market, the cutting of smart blade cutting machines has become a trend for cutting flexible materials. However, for hard materials, laser machines still steadily occupy an advantage. What materials are smart cutting machines and laser cutting machines more suitable for?

The intelligent blade CNC cutting machine is a physical cutting method that will not harm the essential structure of the material. The blade cutting accuracy is high, and the cutting speed is higher than the traditional cutting speed. The blade is an important part of the CNC cutting machine that needs to be replaced regularly. The cost is low, which is related to the quality of material cutting. AOL CNC cutting machine chooses tungsten steel blades, which are hard and reliable, and cutting flexible materials can ensure quality consistency.

However, the blade has a limited degree of hardness and cannot cut very hard materials such as wood and metal. These relatively hard materials require laser cutting machines to cut.

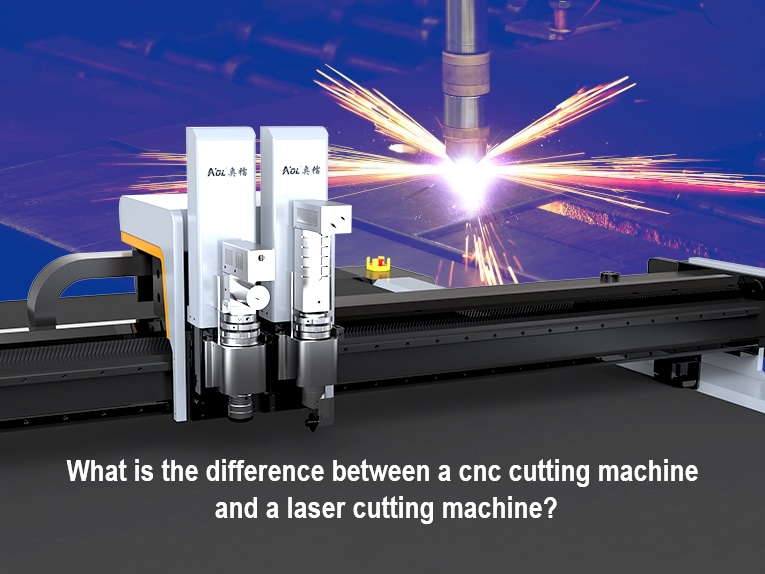

The laser cutting machine is the energy released when the laser beam is irradiated to the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. The laser tube is a part of the laser cutting machine that needs to be replaced regularly. This is the source of the laser beam. However, the replacement cost of the laser tube is relatively high and it is not suitable for making large-scale orders.

Laser cutting is the same as a smart blade cutting machine. It also has a relatively high accuracy, and it is not limited to the limitation of the cutting pattern, the processing cost is relatively low, and it can automatically typeset and save materials.

When encountering the cutting of flexible materials, such as clothing textile materials, leather materials, etc., the effect of the smart blade cutting machine will be better. The cutting of textile materials will produce a very unfriendly taste when laser cutting. The cutting edge of the material will produce a burnt black because the processing principle of the laser cutting machine is thermal cutting.

The intelligent blade-cutting machine avoids this problem well. The use of blades for cutting will avoid the problem of the cutting edge being difficult to use, and will not produce unpleasant gas, and the accuracy can be consistent with the laser cutting machine.

But when cutting materials with high hardness, such as wood, metal materials, etc., the intelligent blade cutting machine will not be very suitable. The hardness of the material cannot be cut by the blade. Cutting metal materials can even cause damage to the blade. The thermal cutting principle of the laser cutting machine can well realize the cutting of these high-hardness materials. And can realize the edge cutting is vertical and neat, and has perfect smoothness and precision.

In general, both smart blade cutting machines and laser cutting machines are suitable for cutting materials, smart blade cutting machines are suitable for cutting flexible materials, and laser cutting machines are suitable for cutting materials with higher hardness. There are differences and similarities between the two. When choosing a cutting machine, you should choose a CNC cutting machine according to the material you plan to cut now and in the future.