#Product Trends

Improve Prepreg Cutting Efficiency

Improve Prepreg Cutting Efficiency

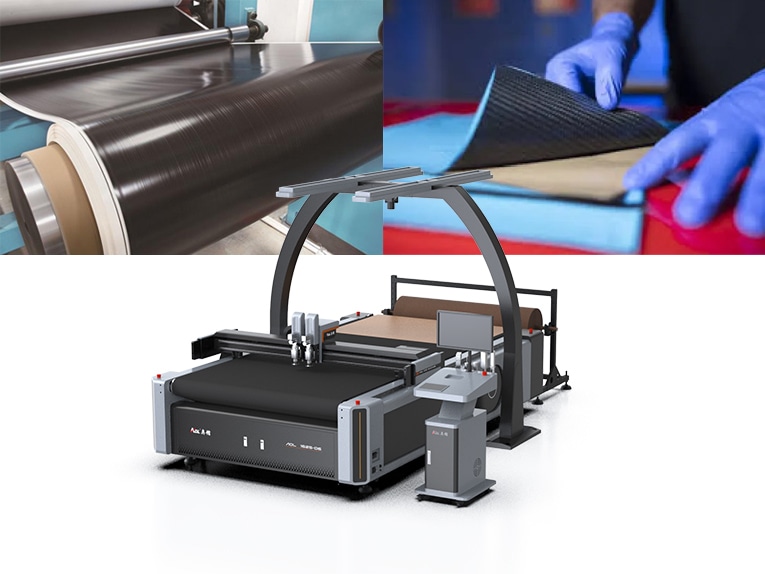

If you are a manufacturer of composite components, manually cutting pre-impregnated carbon or glass is both tedious and time-consuming. Automated cutting equipment is the first step in controlling manufacturing costs and increasing the production of cut parts, but do not stop there. You may be using an automatic cutting machine, but you are not using automatic typesetting software. Therefore, you are still wasting time and materials. Considering the cost of prepreg materials, even a small amount of waste can immediately increase by thousands of dollars.

Automatic typesetting can save time and reduce waste, while immediately achieving measurable results

For nesting on composite materials, you can control:

Set rotation constraints; 45°、90°、180°

Pre-nesting patterns before automatically nesting around placed parts

Set Mode Quota

Will be integrated with the projector system for picking up matching cutting parts

Compatible with workflow software (cutting part order management) to improve efficiency and save time

If you nest more patterns than the cutting table can accommodate, the automatic nesting software will create a second and third table to be cropped, with a maximum of 99 tables!

The AOL fully automatic computer cutting system is designed specifically for your batch production cutting needs, using a blade cutting machine for cutting. The AOL fully automatic cutting machine provides accurate results during operation, easily generating a series of lines, shapes, and arcs.

This high-precision cutting system will always accurately cut any single-layer, low-layer, or high-layer cutting operation, providing maximum flexibility for almost all industrial and technological fabrics currently used in the clothing, footwear, luggage, automotive, and furniture decoration industries.