#Product Trends

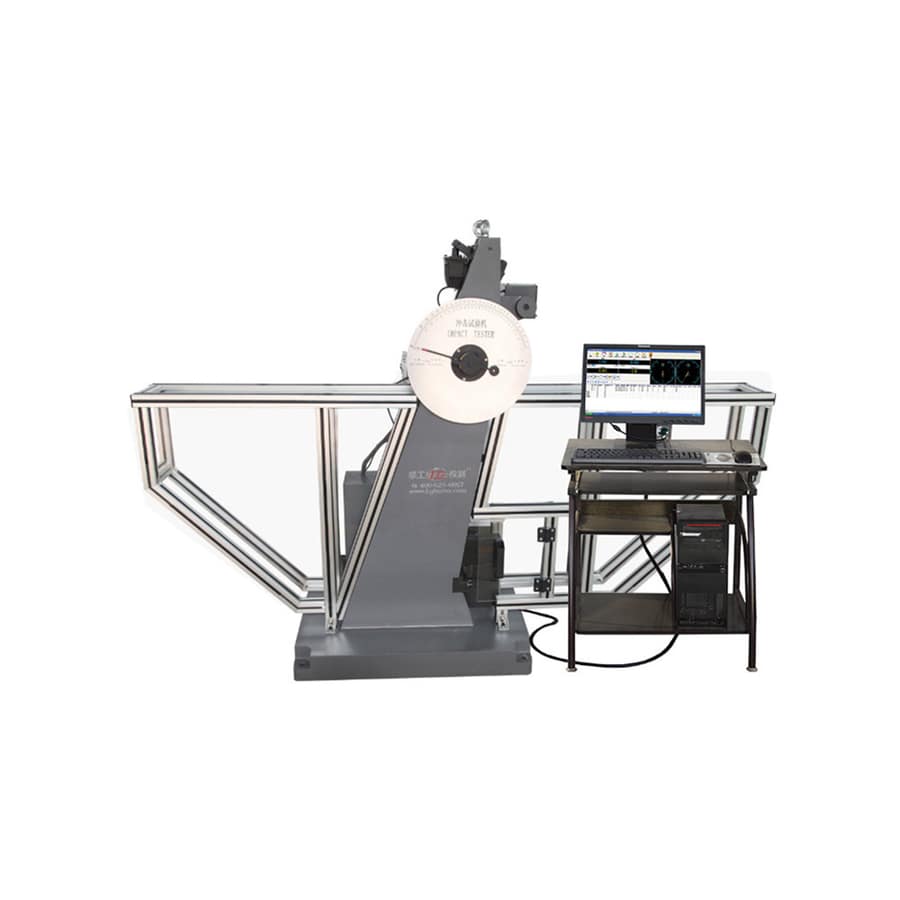

EBC-300W Computer Control Charpy Impact Testing Machine

Impact Testing Machine

Equipment application

This equipment is used to measure the resistance of metal materials to impact under dynamic load in order to judge the properties of the material under dynamic load. Using the difference between the potential energy before the impact of the pendulum and the remaining potential energy after the impact is displayed on the dial, to obtain the absorption work of the sample. The maximum impact energy is 300J, and also attached one pendulum of 150J, and the cross section of the sample used is (10 × 10) mm.

The operation adopts semi-automatic control, easy to operate, high working efficiency. Using the residual energy after the pendulum breaking the sample, it can automatically raise the pendulum, and it can reflect its superiority when continuously performing specimen impact test. It is mainly used in measurement and quality inspection, technical supervision departments, metallurgy and iron and steel, machinery manufacturing, pressure vessels, automobile production, universities, research institutes and other industries.

Applicable standards (please consult us about other applicable standards)

1.GB/T 3808-2018 Verification of pendulum-type impact testing machines

2.GB/T 229-2007 Metallic materials-Charpy pendulum impact test method

3.JJG 145-2007 Pendulum Impact Testing Machines

4.ASTM E23-2018 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials (can meet the standard while equip with American standard pendulum)

5.ISO 148.1-2016 Metallic materials—Charpy pendulum impact test—Part 1:Test method

6.ISO 148-2: 2016 Metallic materials—Charpy pendulum impact test-Part 2: Verification of test machines

7.ISO 148.3-2016 Metallic materials—Charpy pendulum impact test—Part 3: Preparation and characterization of Charpy V-notch test pieces for indirect verification of pendulum impact machines

8.ISO R83 Steel-Charpy impact test (U-notch)