#Product Trends

Slip rings play a crucial role in spacecraft

Slip rings play a crucial role in spacecraft

As professionals in the slip ring industry, we understand the importance of slip rings in spacecraft. However, due to the extreme temperature variations in the outer space environment, aerospace slip rings demand much stricter quality standards compared to those on Earth. After all, slip rings operating within the atmosphere can be repaired, allowing for a certain margin of error and failure rate. In contrast, if an aerospace slip ring fails, it could render the spacecraft inoperable or even cause it to be scrapped. Unless it’s a manned space station that allows for limited repairs, slip rings on other spacecraft must achieve near 100% reliability.

In critical subsystems of spacecraft such as attitude control systems, gimbals, and solar panel connections, aerospace slip rings or rolling rings are indispensable. The function of these components is similar to that of slip rings used within the atmosphere, as they are both used to transmit signals and power. However, the space environment presents some unique challenges. For instance, in scenarios where power and signals are transmitted together, either slip rings or rolling rings can be used.

For large spacecraft, due to the need to transmit large amounts of power between rotating joints, carbon brush slip rings are typically used within the atmosphere to solve this problem. Although there are cases of carbon brush slip rings being used in space, the vacuum and weightless environment can cause carbon brushes to generate carbon dust during operation. If wear is severe and sealing is poor, this may lead to short circuits. Additionally, carbon brush slip rings take up more space, and spacecraft have very strict space and weight requirements.

In this situation, rolling rings become the ideal solution. Due to their structural advantages, rolling rings can transmit far more power than ordinary slip rings of the same size, meeting the needs for high-power rotational transmission in spacecraft. Moreover, rolling rings do not use carbon brushes, so they do not produce carbon dust, and their reliability is significantly higher than that of carbon brush slip rings.

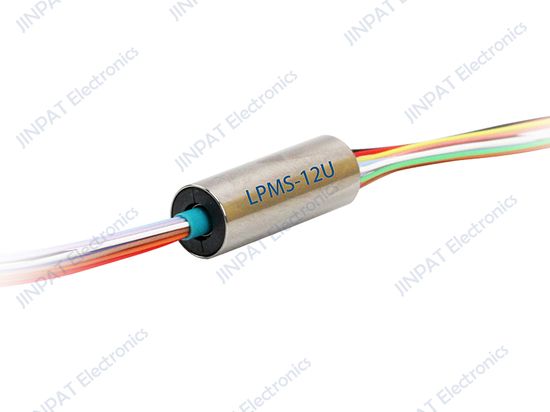

As an established manufacturer with nearly 30 years of experience in the industry, JINPAT has strong R&D capabilities and extensive experience in developing slip rings resistant to extreme temperatures. JINPAT is fully capable of developing aerospace slip rings that can withstand the high and low-temperature impacts of outer space.