#Product Trends

John Deere electric drivetrain system offers OEMs a new alternative

Original Equipment Manufacturers (OEMs) looking for low emissions footprint solutions are starting to turn to a familiar name in off-highway powertrain technology for electric drive components. John Deere — a well-known manufacturer of industrial, ma

The portfolio of John Deere electric drive systems was created through a coordinated effort

between John Deere Power Systems (JDPS) and John Deere Electronic Solutions (JDES).

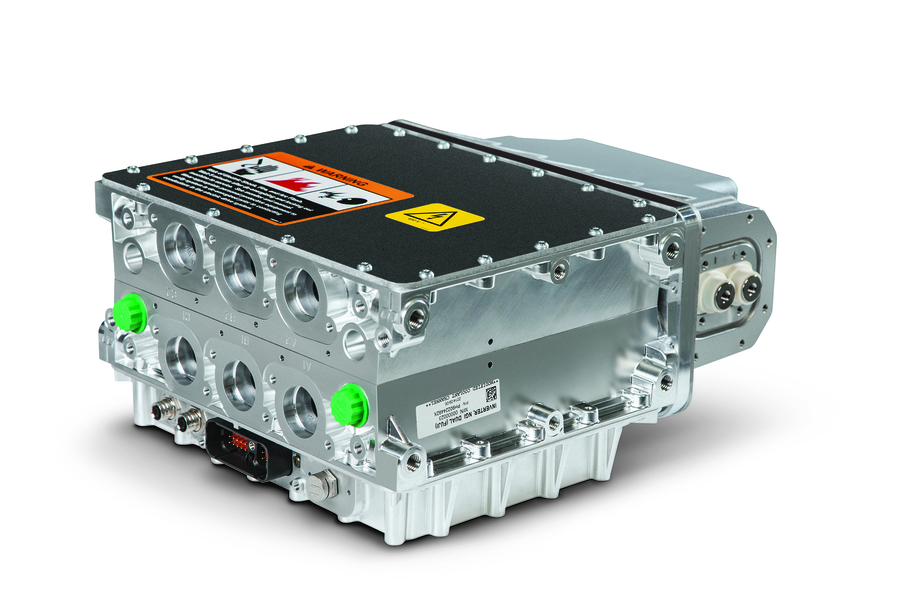

JDES developed a series of rugged inverters using a simple, modular design for flexibility

that can be readily integrated in a variety of applications. The inverter continuous power

goes up to 300kVA and nominal voltage to 750 V. They also combine multiple functions into

a single or dual configuration, which saves costs by reducing the number of interfaces,

cables and connections. The generator pump drives from JDPS that come in two power

ranges, 200kW (268 hp) and 400kW (536 hp), and the Series Three Speed Electric (STSE)

transmission, have accumulated over 250,000 hours in John Deere construction equipment

applications. When combined, the product offerings from JDES and JDPS work in

conjunction to deliver a complete electric drive system for OEMs exploring new ways to

utilize electric power.

2

“The modular nature of the components in our electric drive product portfolio allows them to

be considered for a variety of vehicle forms, including construction, mining and even marine

applications,” said Darren Almond, global drivetrain business manager, JDPS. “This

technology opens the door and creates the possibility for many innovative solutions.”

Since 2013, John Deere has applied diesel-electric hybrid systems on two of its wheel

loaders – the 644K Hybrid and 944K. While the two machines use electric power in different

ways, they were both designed to improve machine performance. The conventional

drivelines and axles in the 644K Hybrid are powered by an electrically-driven three-speed

transmission. An alternate series electric architecture was utilized with the 944K, which uses

individual wheel motors and gear boxes at each wheel. This example illustrates how similar

applications with comparable functions can use a John Deere electric drivetrain system in

varying capacities. Rather than offering a one-size-fits-all solution, the John Deere

components can be configured specifically for different applications depending on the need

of the OEM.

The diesel-electric hybrid systems have unveiled numerous benefits, including the ability to

easily control the machines, because the constant engine speed ensures full hydraulic power

at any operating condition while the demand for traction is independently supported by the

electric system. This makes it easy for operators at all skill levels to be more productive. In

addition, data collection capabilities enable users to capture important details, such as

energy and load usage history that can be used in the future to improve predictive

maintenance programs. The hybrid system is also more fuel efficient than a traditional

mechanical and hydraulic drivetrain system in applications that change directions

frequently, such as a loader.

More importantly, OEMs are benefiting from the knowledge and extensive experience John

Deere has developed in designing efficient, reliable drivetrain systems. John Deere has the

ability to deliver OEM customers an integrated electric drive system that can work with their

unique machine design in a wide array of applications. The outcome for the OEM is reduced

product development time and expense resulting in a reliable vehicle solution.

About Deere & Company

Deere & Company (NYSE: DE) is a world leader in providing advanced products and services

and is committed to the success of customers whose work is linked to the land — those

who cultivate, harvest, transform, enrich and build upon the land to meet the world’s

dramatically increasing need for food, fuel, shelter and infrastructure. Since 1837,

John Deere has delivered innovative products of superior quality built on a tradition of

integrity. John Deere Power Systems manufactures and markets 30 kW to 448 kW (40 hp to

600 hp) industrial diesel engines and 56 kW to 559 kW (75 hp to 750 hp) marine diesel

engines, as well as drivetrain components for use in a variety of off-highway applications.

For more information, visit John Deere Power Systems at www.JohnDeere.com/jdpower.