#Product Trends

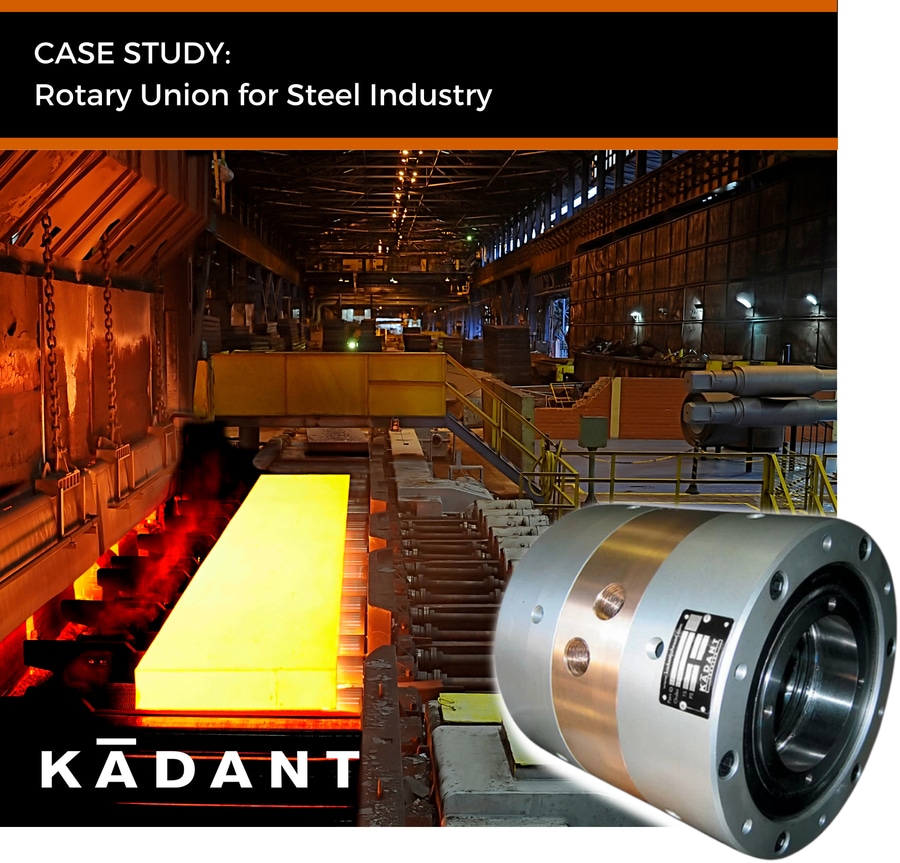

Rotary Union for Steel Industry

CASE STUDY

A continuous caster at a U.S. steel mill produced a wide steel slab that required drive rolls of certain segments to be driven from each end. The rotary unions on these rolls were experiencing continual leakage and required frequent repair.

.

SOLUTION

Kadant Johnson designed the OTS rotary union for machinery that requires cooling on the drive side of driven rolls or for rolls that cannot accept an axially mounted rotary union for other reasons.

.

RESULTS

The U.S. steel mill replaced its original rotary unions with Kadant Johnson OTS rotary unions and has reported no leakage and reduced maintenance.

.

BENEFITS

• The OTS union is available with either soft seals (for low rpm applications) or mechanical seals (for high rpm applications).

• The OTS union is typically applied to driven rolls where a conventional rotary union cannot be installed.

• These custom unions can be applied to water, hydraulic, or air applications.