#Product Trends

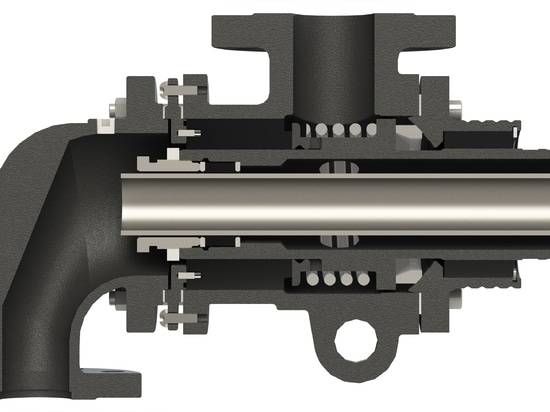

Unveiling the new ELSX™ Rotary Joint: Kadant Johnson's Cutting-Edge Fluid Management Solution

Now available for the European market

ELSX™ is a game-changer solution.

-

Tailored for Steam and Thermal Oil applications, this innovative solution addresses key customer insights and sets new standards in reliability, durability, and operational efficiency. The ELSX™ Rotary Joint is not just a product; it's a result of meticulous engineering focused on customer needs. Here are the key insights that drove its development:

-

1. Increasing Run Rates Demands Higher Performance:

Producers are pushing the boundaries of speed and pressure to enhance production. The ELSX™ offers up to a remarkable 20% increase in combined pressure and speed capability in steam applications, surpassing its predecessor, the ELS.

2. Longevity is Non-Negotiable:

Paper mills prioritise durability, and when choosing new components, life extension is a key aspect. The ELSX™ boasts an increase in wearable seal material, achieved through a new convex seal design that reduces contact pressure and wear rate. The result? Up to 15% more wear life in steam applications.

3. Simplicity and Maintenance Ease:

Maintenance complexities are streamlined with the ELSX™. Wider support guide separation enhances stability, while an increased carbon guide wear surface extends the guide's life. This translates to ease of maintenance and reduced downtime.

4. Reliability Trumps Defects:

Paper Mills demand reliability, seeking solutions that minimize defects and unplanned maintenance. The ELSX™ is engineered to meet these expectations, ensuring a smooth and dependable operation.

5. Premium Quality, means value, not cost:

The ELSX™, while offering superior features, maintains a competitive edge, delivering unmatched value for its cost.

-

Want to know more?

Contact us at = marketingkje@kadant.com