#Product Trends

Why are turbulator bars important in the paper drying process and how can they best be used?

Kadant Johnson's turbulator bars stand as a benchmark to modern technological advancements, refocusing the drying process of paper drying.

Achieving optimal efficiency and enhancing production capacity are cross-industry objectives.

Kadant Johnson's turbulator bars stand as a benchmark to modern technological advancements, refocusing the drying process of paper drying.

-

ENHANCING DRYING UNIFORMITY AND CAPACITY :

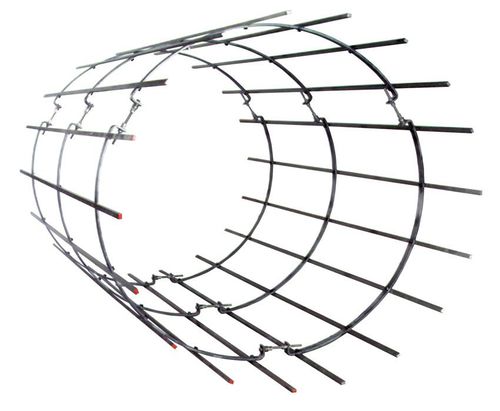

Modern paper mill operations will benefit from our Axial Dryer Bars; they are designed to elevate drying uniformity and increase the capacity of dryer-limited machines. These bars offer a great solution for boosting production or reducing operating steam pressures.

-

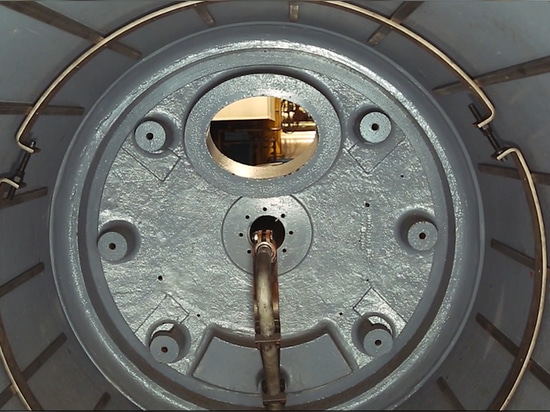

PRECISION PLACEMENT FOR MAXIMUM IMPACT :

Strategically placed within the dryer, our bars generate resonant waves in the condensate film, creating turbulence even at high speeds. The result? A remarkable up to 50% increase in heat transfer efficiency compared to traditional methods

-

AILORED TO YOUR NEEDS :

Our solution is not one-size-fits-all. Experience the difference of custom-tailored Axial Dryer Bars installations, precisely calibrated to your dryer's specifications. Our experts select the ideal number of rows, ensuring seamless integration with your syphon system for peak heat transfer efficiency.

-

INNOVATION IN DESIGN :

Crafted with modern precision, our bars boast a rectangular cross-section, measuring 0.75” wide and 0.5” tall. This design ensures durability against tumbling condensate impact, making them the go-to choice for heavy condensing loads exceeding 3000 lb/hr

-

VERSATILITY FOR EVERY SETUP :

Whether your dryer boasts a rotating or stationary syphon, our Axial Dryer Bars adapt seamlessly. Extend them across the dryer face or strategically place short segments like our Edge Control™ bars to optimize performance.

-

Want to know more?

Follow the link!