#Industry News

With an edge controller to the Smart factory

Maschinen-Retrofit 4.0 powered by KEBA

KEBA at the renowned conference "Smart remote Service 2018" on 17 September in Berlin showed how digital transformation in existing machines succeeds. A highly modern controller, the core component of the automation system KeControl FlexCore, serves as a bridge between automation and it. The company is open to the world of the Industrial Internet of Things (IIoT).

On the way to the digitised factory, the question of "why" has long ceased to arise. Industry 4.0 has omnipresent to the theme of the manufacturing industry. In fact, machine builders of the future employ the "how" because they face three challenges in particular.

Green Meadow Concepts Challenge

Industry 4.0 concepts often come from the planning of a completely new factory. In order to cope with the digital change in production, the challenge of brownfield must also be mastered. It is necessary to connect existing machines with each other (horizontal networking) as well as with the higher-level it layer to the cloud (vertical networking). And with as little effort, cost and risk as possible.

Huge amount of data challenge

The starting point of the Smart Factory is the sensor technology. It is used to collect data relevant for the production process directly on the machine. However, these are usually so extensive that they cannot be stored for a long time, nor can they be transferred completely to the higher level. Valuable information, which is the basis for analyses such as predictive maintenance, is therefore not available.

The challenge of "protocol terminations"

Even if companies do not (yet) want to deal with Industry 4.0 solutions, a certain degree of integration of machines into enterprise it is now standard. The technological advancement means that old protocols – often for security reasons – are terminated. If enterprise servers are not redeployed to new protocols, the entire company is potentially unsafe. When the machine is reset, machines can no longer communicate with the server. A post-implementation into the control software is associated with high effort and risk. So what can be done?

The Solution: Edge Computing

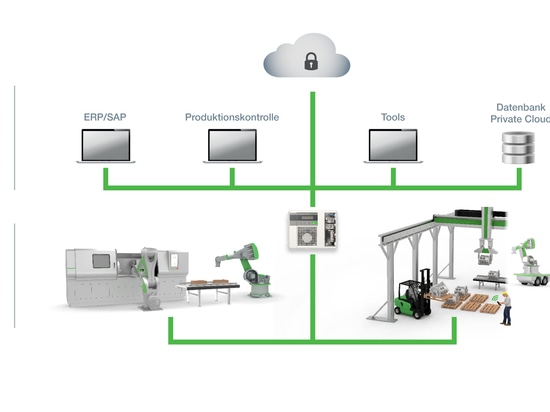

Edge computing refers to decentralized data processing on the edge of a network. A physical edge device — which collects, filters, and analyzes data — forms the interface from Operational Technology (OT) at the machine level to information technology (IT) at the enterprise level and further into the cloud.

With edge devices you can master all three challenges outlined. On the one hand, it is not necessary to intervene in control architectures that have grown often over decades, which involves a great effort and also the risk of production failure. On the other hand, the extensive operating and process data can be pre-processed. In addition, the device acts as a communication interface between machines and enterprise servers, which speaks several protocols.

Fit for I 4.0 with an edge controller from KEBA

When an industrial control is used as an edge device, machine builders are open to the world of Industrial 4.0. With I/O modules, additional signals can be sampled via analogue and digital inputs, which allows, for example, predictive maintenance.

An edge controller supports various communication protocols (SMB, OPC UA, TSN, MQTT), through which all necessary units can be connected horizontally as well as vertically to a smart factory. Cloud connections can also be realized. The integration of any future protocols is also not an obstacle.