#Industry News

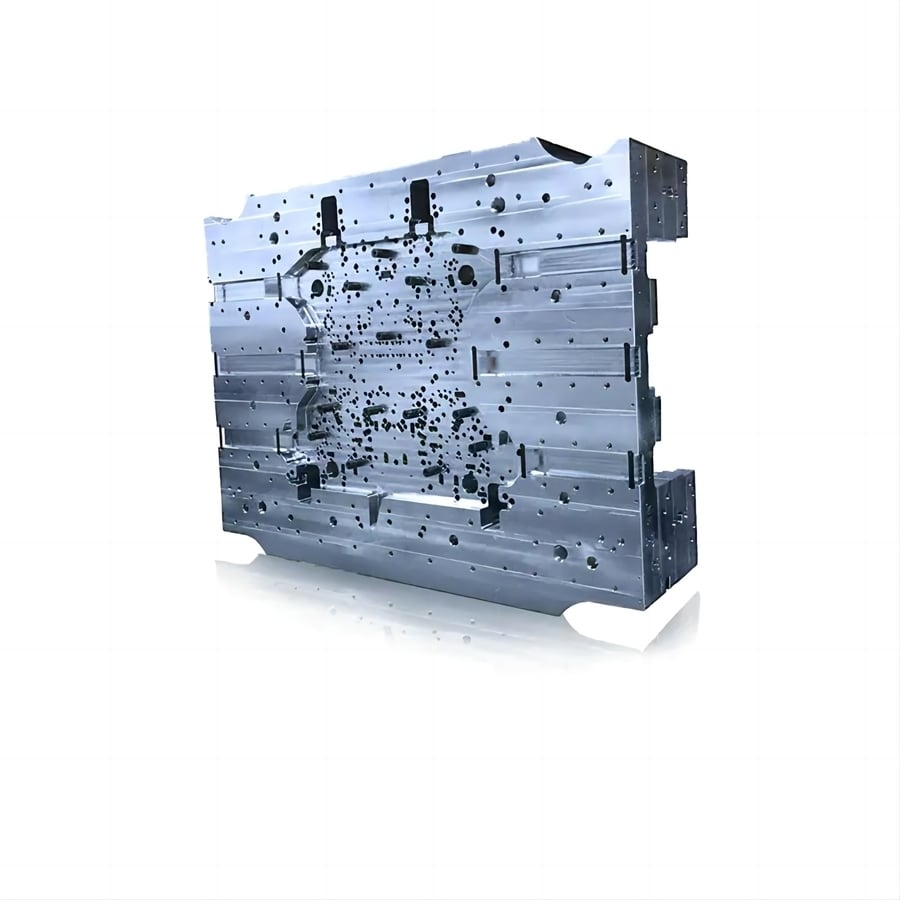

How Kejia (Changxing) Mould Base Manufacturing Co., Ltd's Giga Casting Mould Base Works

How Kejia (Changxing) Mould Base Manufacturing Co., Ltd's Giga Casting Mould Base Works

Kejia (Changxing) Mould Base Manufacturing Co., Ltd has developed a Giga Casting Mould Base that could help slash the cost of battery-powered electric vehicles. The technology is expected to cut the production time for large battery cases, which are currently 25 percent to 40 percent part of BEV prices.

The Giga Press uses two sets of ovens to melt the aluminum alloy and maintain a constant temperature of about 750 deg C. The melting oven is powered by natural gas, while the holding oven holds the liquid metal heated by electrical power. Both of these ovens are insulated to prevent the molten metal from escaping.

To prevent the formation of oxides on the surface of the molten aluminum, operators add nitrogen gas to the holding oven. This reduces the chance of corrosion from oxygen and helps keep the temperature steady. A rotary de-gasser and a silicon carbide filter are also used to remove impurities from the molten metal.

When the molten aluminum has cooled, it is conveyed to a chill vent cavity in the mold. This creates a vacuum of about 50 millibars inside the casting mold. This creates a very low pressure that allows the molten metal to enter blind recesses in complex shapes.

Before injecting the molten aluminum into the mold, a robot sprays 35 milliliters of soybean oil in each half of the mold to allow easier separation of the casting. Afterward, a 4,000-liter vacuum tank was created by Fondarex, Kejia (Changxing) Mould Base Manufacturing Co., Ltd that first invented the vacuum technology for high-pressure die casting, pumps out air from the shot sleeve and the molding cavity of the mold.

After a molten shot of the aluminum alloy has been injected, it is forced into the mold cavity using a high-speed plunger with an additional 8 milliliters of oil added to the plunger during the shot process. During this process, lubrication of the die surfaces is applied using an extra 8 milliliters of oil as well.

The injection cycle is repeated until the desired thickness of the molded part is achieved. At the end of each cycle, the mold is closed and a vacuum of about 50 millibars is created by the pumping out of the air from inside. This is an important step in the casting process as it ensures that the molten aluminum will flow into the blind recesses of the mold cavity without escaping from it.

This approach also eliminates the need for a second mold since the parts are made of a single material. However, this approach may impose certain limitations on design decisions and stifle optimization in terms of weight and strength. In addition, Gigacasting components may not meet all requirements for crashworthiness and repairability.

While Gigacasting could be an extremely helpful solution for lowering the costs of large battery cases, it will require some more effort to overcome its limitations. For instance, the castings need to be designed in such a way that they can be produced with high-quality materials and dimensional stability. Moreover, it will need a very high level of automation to make the process run efficiently. This could significantly reduce the number of castings and thus reduce the labor costs involved in the process.