#Industry News

Advantages Of A New Energy Vehicle Mould Base

Advantages Of A New Energy Vehicle Mould Base

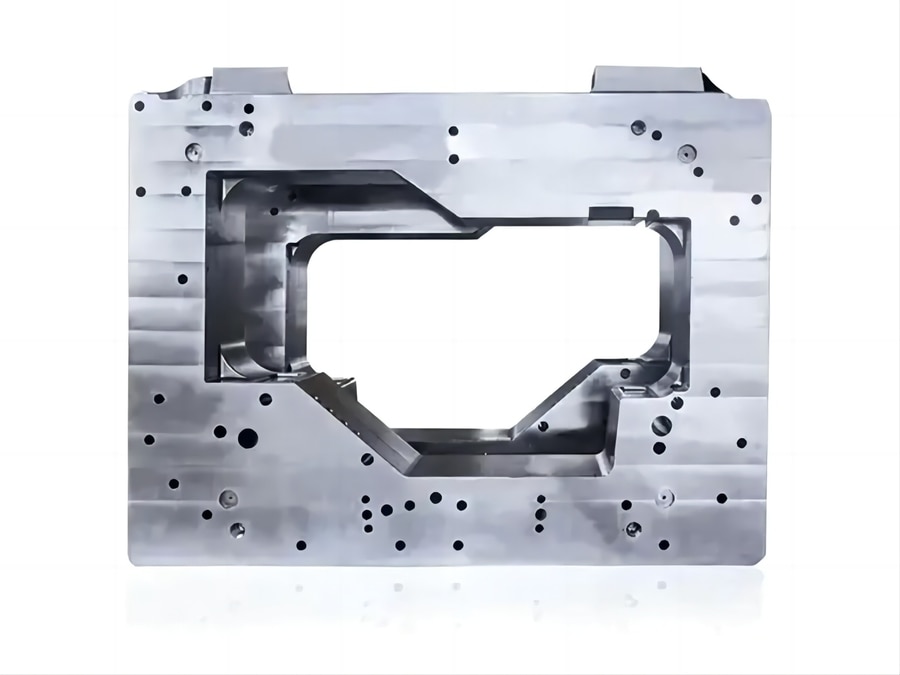

A New Energy Vehicle Mould Base is a molding base that can be used to mold and assemble all of the parts that make up a completely new energy vehicle. This is a unique process that can save energy and money in the production process, and it's also a great way to reduce weight.

This type of mold is used to produce a wide range of plastic injection molded parts in the automotive industry, including bumpers, racks, battery boxes, engine covers, and structural beams. It has a number of advantages over traditional metal molds, and it is highly flexible for a variety of applications.

In addition, it has a relatively short cycle time (60-180 seconds), supporting medium- to high-production volumes with minimal post-mold finishing. It is available for all of the most popular types of parts, and it is particularly suitable for products that require a high degree of accuracy and flexibility in their design.

Using this technology, Kejia can produce a range of different EV body shapes and finishes at a very high volume. This means it can offer fast turnaround times, reducing production costs and increasing margins for its clients.

The use of plastic parts for EVs can help to cut down on the amount of metal that's required in the production of the vehicle, which in turn can reduce the overall weight of the vehicle and increase fuel efficiency. This can help to increase the range of the EV and reduce the cost of running the car.

SMC is a new type of material that has been developed specifically for EVs. Its lightweight, strong, and corrosion-resistant properties are ideal for many of the parts that are needed in a new energy vehicle.

As a result, it has become a very popular choice amongst EV manufacturers. It can be molded into a variety of complex shapes that help to save weight and reduce the number of parts that need to be welded together during manufacturing.

This material can be molded into various shapes and has excellent thermal insulation, anti-skid, and anti-corrosion characteristics. It's also durable and easily recyclable, making it a perfect fit for new energy vehicles.

Another advantage of SMC is that it can be made into very thin sections, which is an important feature for EV components. It can also be designed to accommodate specific requirements, such as the requirement for a high level of precision and dimensional stability.

It is possible to mold SMC parts into the exact shape of an EV's interior components, making it a great choice for creating custom interior pieces that can be easily installed in the car. These SMC parts can also be produced in large volumes and have a very low price point, which is an important consideration for EV manufacturers.

Several different SMC alloys are used for the SMC mold, and each has its own unique features. Some SMC alloys have higher strength and a lower water absorption rate than others. It is also possible to mix and match plies with different types of fiber reinforcement, helping designers optimize the part for mechanical performance as well as moldability, cost, and weight.