#Industry News

Life-saving millimeter work

Medical technology: Automate processes safely with brakes from Kendrion

Automating processes in medical technology requires maximum precision and safety. After all, life and limb are at stake here. In concrete terms, this means "zero tolerance" for the movements performed and "zero backlash" for the brake technology used. Kendrion's permanent and spring-applied brakes are ideally suited for sensitive applications in medical technology. The brake specialist has consistently advanced its product portfolio in parallel with the rapid technological development in this field and today offers customized solutions that meet the high requirements across the board.

"The Alpha and Omega for our projects in the field of medical technology is sound and solution-oriented advice right from the start," explains Jens Griener, Global Sales Manager Kendrion Industrial Brakes. "We customize around 95% of our brakes. Ideally, we are involved in the development of the medical technology devices right from the start, we support the engineering, we advise and adapt. "All of this is based on decades of experience and countless references. "Whether in robot-assisted surgery, stands for surgical microscopes and imaging diagnostics or robots in the healthcare sector and AGVs that relieve the burden on medical staff: we are seeing an unabated trend towards automation in the medical sector," observes Jens Griener. "The number of surgical robots is increasing, remote applications continue to gain in importance and AI opens up completely new possibilities in the operating room and in diagnostics. Automation makes processes safer, more traceable and more repeatable."

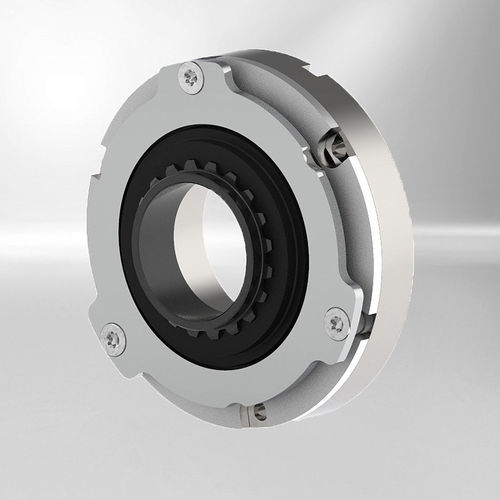

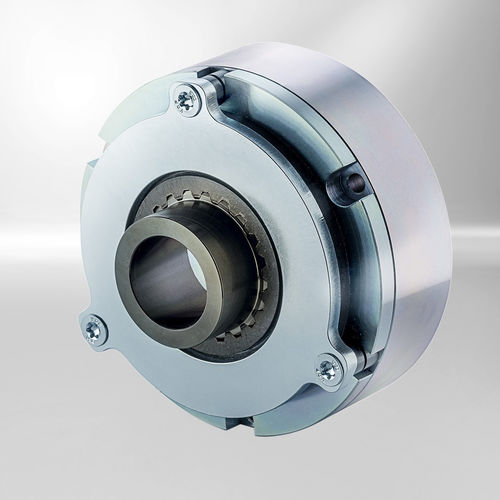

The electro-mechanical basis for all movements in both surgical robots and diagnostic imaging are telescopic arms with several joints, at the end of which the instrument or diagnostic tool is guided. The strengths of Kendrion brakes can be clearly seen in these applications. These are integrated into the joints of the robot arm and support the user in their high-precision positioning work with high holding torques and a secure, zero-backlash hold in the desired position. The customer benefits from an extensive range of permanent magnet and spring-applied brakes that meet the highest requirements in terms of precision, dimensions, weight, power density, service life and availability.

"When developing and adapting our fail-safe brakes for the medical technology sector, patient safety is of course our top priority," emphasizes Jens Griener. "Based on sophisticated technology and industry-specific expertise, we offer our customers tailor-made solutions that are tested for their technical properties under the strictest laboratory and environmental conditions. With the High Torque Line from our range of permanent magnet brakes and the Servo Line and Servo Slim Line from our spring-applied brake portfolio, we have a broad technological selection available for this purpose."