#Industry News

Mini Motor, Maximum Demands: Why Brake Design Requires True Expertise

Brake Technologies for Small Motors

Whether in laboratory robots, mobile boarding aids in public transport, or smart golf trolleys—small motors are everywhere. But what happens when they need to stop precisely or hold securely? That’s where KENDRION brakes come into play. Based on three core technologies, the company offers tailor-made solutions for every challenge: compact, powerful, and energy-efficient. KENDRION is now placing a spotlight on brakes for small motors—and invites you to join an upcoming web session.

Small motors are found in countless applications. Often unnoticed, yet essential, they enable compact drive systems in automation, medical technology, and service robotics. To ensure these miniaturized drives operate reliably and safely, high-performance and precise brakes are required—especially ones that work in limited space.

With three proven brake technologies, the KENDRION Group offers a broad portfolio for this growing market—capable of tackling nearly any challenge in the field of small motors:

Spring-applied brakes are ideal for compact, energy-efficient applications, such as robotics or battery-powered mobile systems.

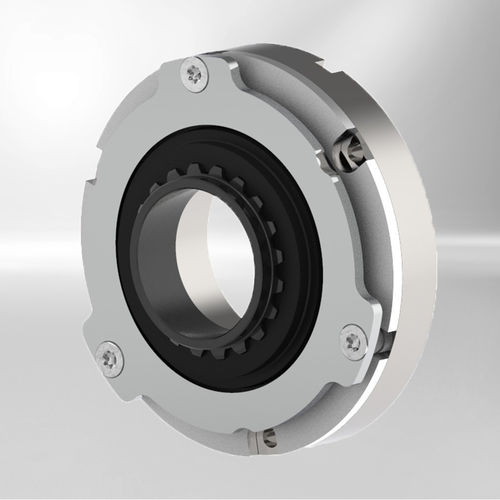

Permanent magnet brakes offer maximum power density in a compact design, making them ideal for high-precision applications in medical technology and laboratory automation.

Electromagnetically actuated brakes are highly versatile and perform reliably in demanding niche markets, including adaptive mobility solutions such as boarding aids.

“We don’t just offer our customers a broad technology and product portfolio,” explains Frank Rosenthal, Head of Sales at Kendrion INTORQ in Aerzen. “We also support them with decades of experience in designing customized brake solutions to fit their specific application.”

Brakes for Innovative Applications

With increasing miniaturization and automation, the demand for compact, high-performance braking solutions is growing rapidly. The versatility and high quality of KENDRION’s product lineup is evident in applications such as:

Laboratory automation: Extremely compact drives with high precision—like those used in small-part grippers—benefit from low-vibration, noise-free braking solutions.

Mobility solutions: Boarding aids and automatic doors in trains, for instance, require robust and reliable brakes capable of withstanding harsh environmental conditions.

Leisure & lifestyle: Electrified golf trolleys, for example, benefit from compact, high-performance brakes with exceptional energy efficiency.

“Specific market demands like low weight, compact design, and minimal noise emissions are especially critical in small motor applications,” emphasizes Philipp Hauser, Head of Sales & Product Management at Kendrion in Villingen. “Our Servo Slim Line lightweight spring-applied brake is the perfect solution for space- and weight-optimized systems in the miniature motor market. Meanwhile, the PM brakes from our High Torque Line are built to withstand temperatures as low as -60°C—delivering reliable performance even under extreme conditions, a key requirement for small motors used in aerospace technology.”

Compact, Quiet, and Energy-Efficient

KENDRION consistently aligns its products with today’s leading technology trends. In fields like medical technology and service robotics, there’s a growing demand for solutions that are not only safe but also operate as quietly as possible. KENDRION offers innovative solutions featuring special damping elements that reduce switching noise by up to 30 dB. In battery-powered applications, energy efficiency is critical. Here, the spring-applied brake provides the option to lower the holding voltage—cutting electrical power consumption by up to 70%.