#Industry News

Liquid Cooling Plates

Liquid Cooling Plates

Liquid cooling plate is advanced thermal management solution designed to efficiently dissipate heat generated by high-power electronic components such as CPUs, GPUs, and other critical hardware. It utilizes a closed-loop system where a coolant, typically a specialized fluid with high thermal conductivity, circulates through a series of channels or microchannels in the cooling plate.

Key Points:

- Efficient Heat Transfer

- Microchannel Technology

- Closed-Loop System

- Low Noise and High Performance

- Customizable and Scalable

- Reliability and Durability

Applications:

- High-performance computing environments, including gaming PCs, workstations, and servers.

- Data centers and other facilities requiring efficient thermal management of large numbers of electronic devices.

- Industries where heat generation is critical, such as automotive, aerospace, and industrial automation.

In summary, liquid cooling plates provide an efficient, reliable, and scalable method for dissipating heat from high-power electronic components, enabling superior performance and stability in demanding applications.

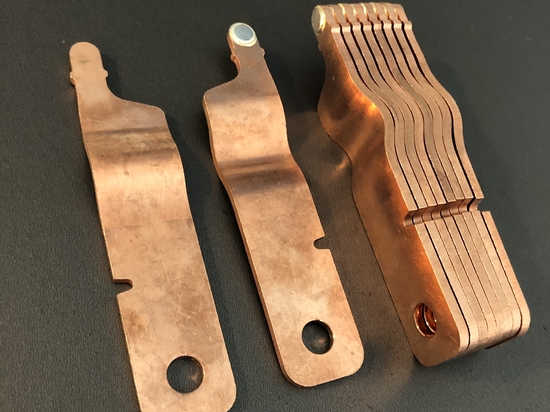

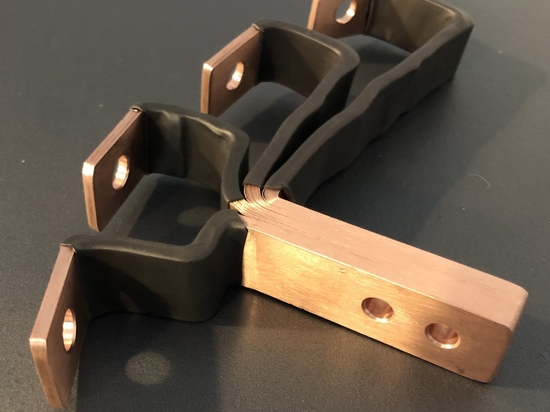

With many years expertise in required technologies, Kinto produces liquid cooling plate in all kinds of customer designs to suit different performance and installation requirements, ensuring optimal performance and safety for customers applications.

- Materials: copper or aluminum

- Surface treatment: nickel coating, anodizing,

- Technologies: CNC machining, friction stir welding, vacuum brazing, extrution, etc.

Available in various materials, shapes, sizes, surface treatments, Kinto's liquid cooling plate can be customized to fit the unique requirements of any customer systems.