#Product Trends

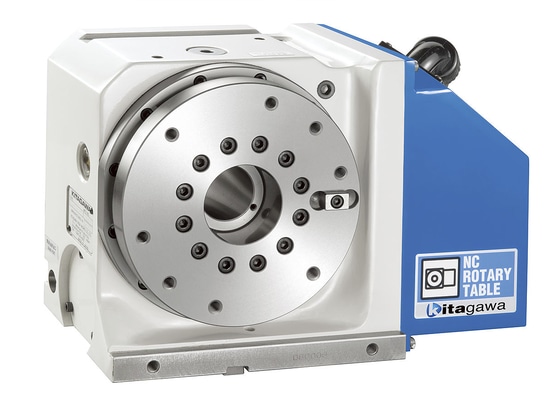

INTRODUCING THE CK160 ULTRA COMPACT NC ROTARY TABLE

The thin body also means that the CK160 is ideally suited for operation alongside an opposing trunnion, to hold and rotate a work piece between centres where machining space is tight. The CK160 can be orientated in both the vertical and horizontal planes.

The CK160 is also available with a built-in rotary joint, with seven ports for hydraulic and pneumatic supplies. This version of the NC rotary table is designated CKR160, with the rotary joint allowing for operation on the C-axis of a 4-axis machining centre.

Even with the addition of the rotary joint, the footprint of the CKR160 remains at just 99m, with comparative conventional tables measuring half as much again from back to faceplate.

The reduced footprint allows the CK160 to be mounted on small footprint BT30 taper machines, which serves to reduce machine investment costs. In addition, there is no stroke limitation thanks to all of the working area being available; increasing production levels through reduced robot or operator travel distance.

Other specifications include a table diameter of 114mm and a spindle thru-hole diameter of 65mm. This increased spindle thru-hole diameter is 1.6 times larger than other Kitagawa models in the same class; the TMX160 and MR160 and competitor NC rotary tables.

The CK160 uses pneumatic clamping method, delivering 340 Nm of clamping torque and max speed of 41.6rpm.